Choosing the Right Hygienic Bearing House: 5 Types Explained

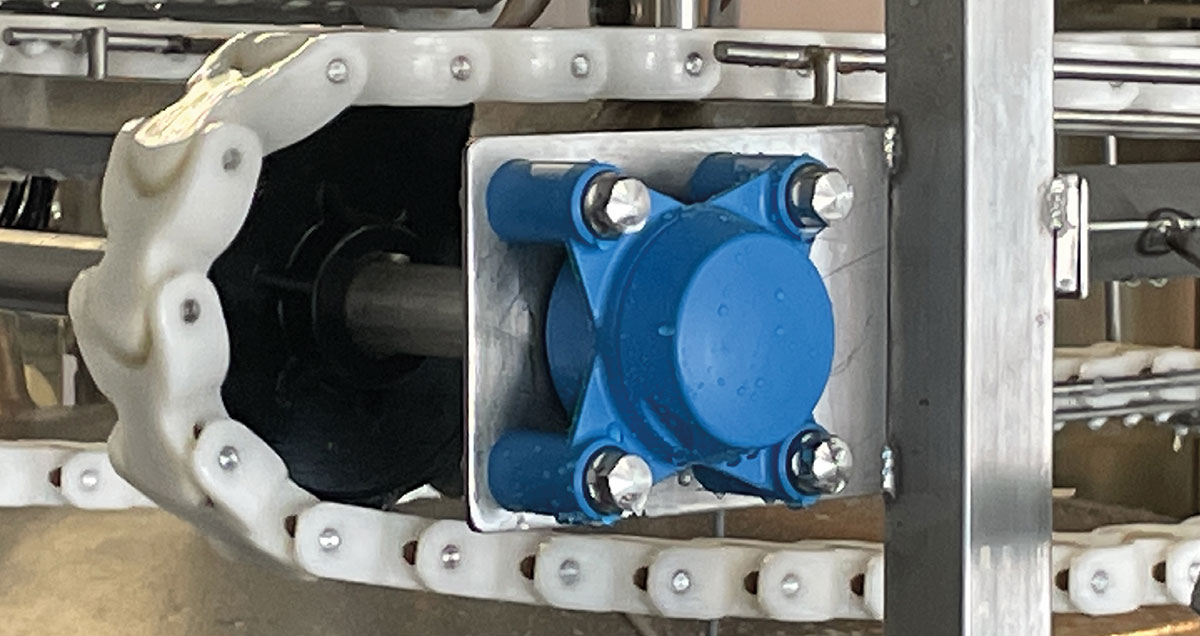

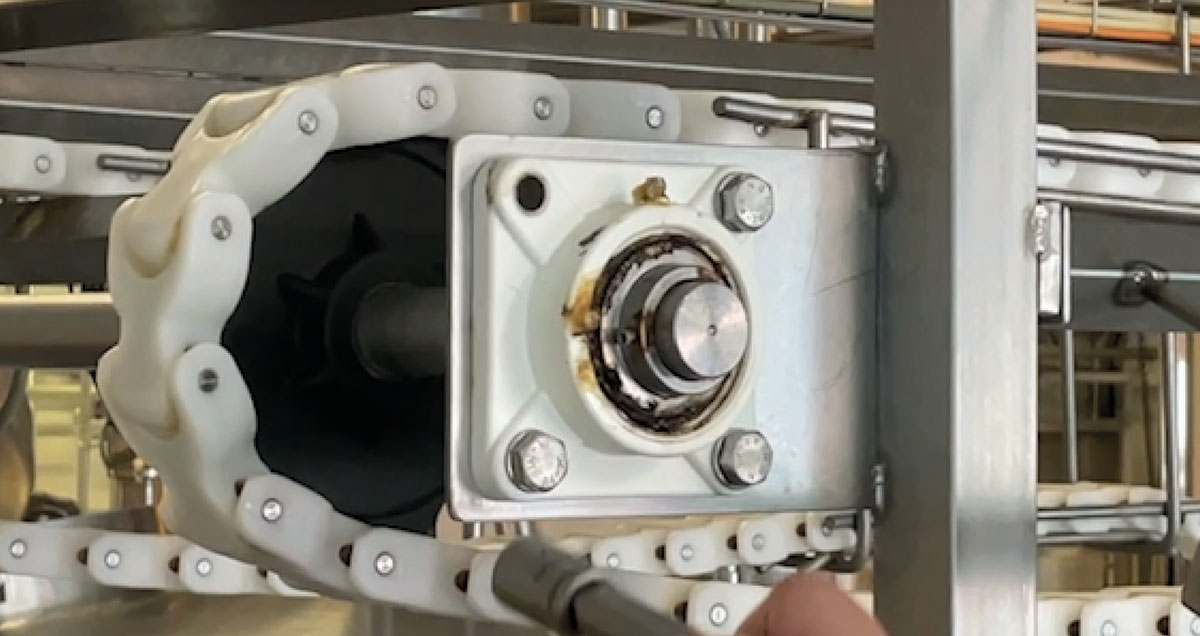

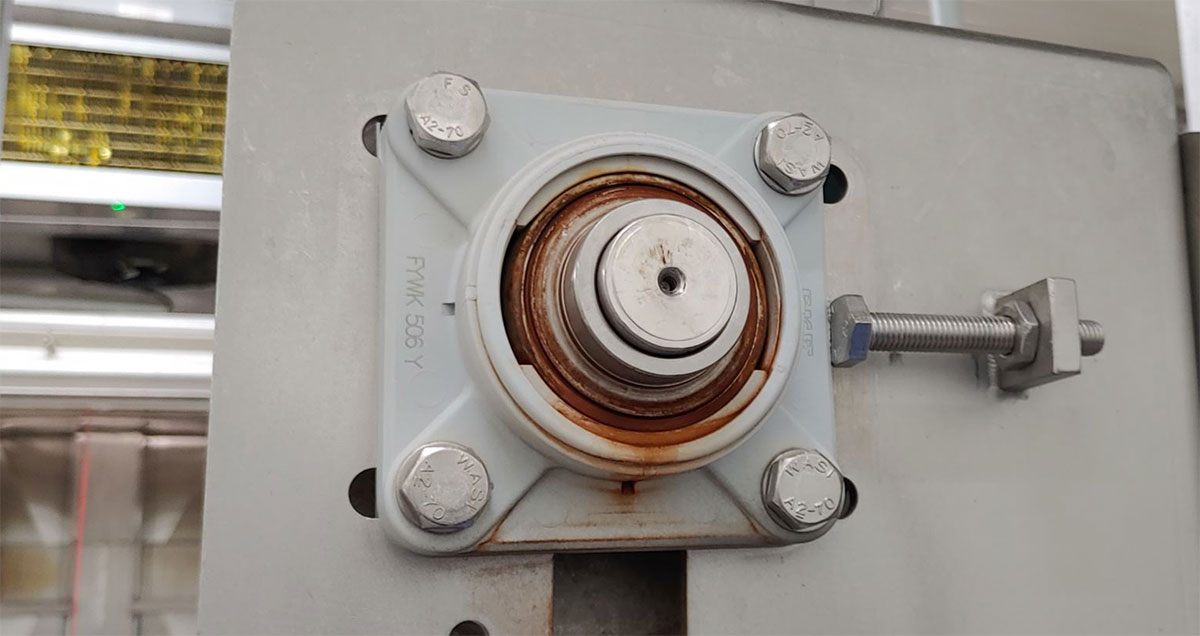

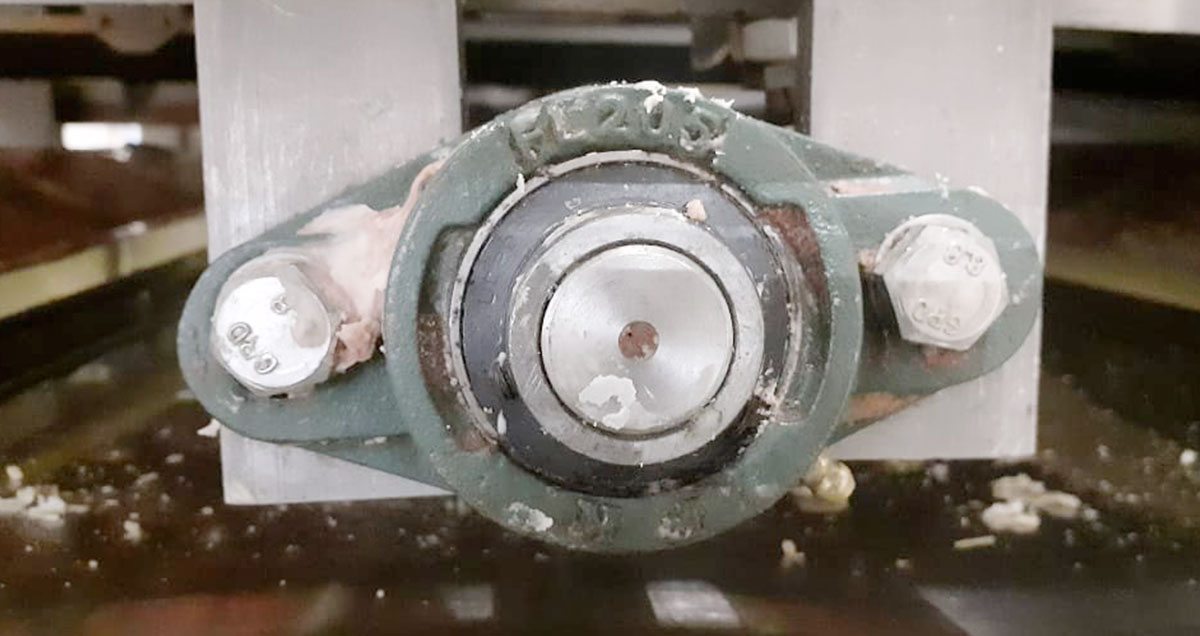

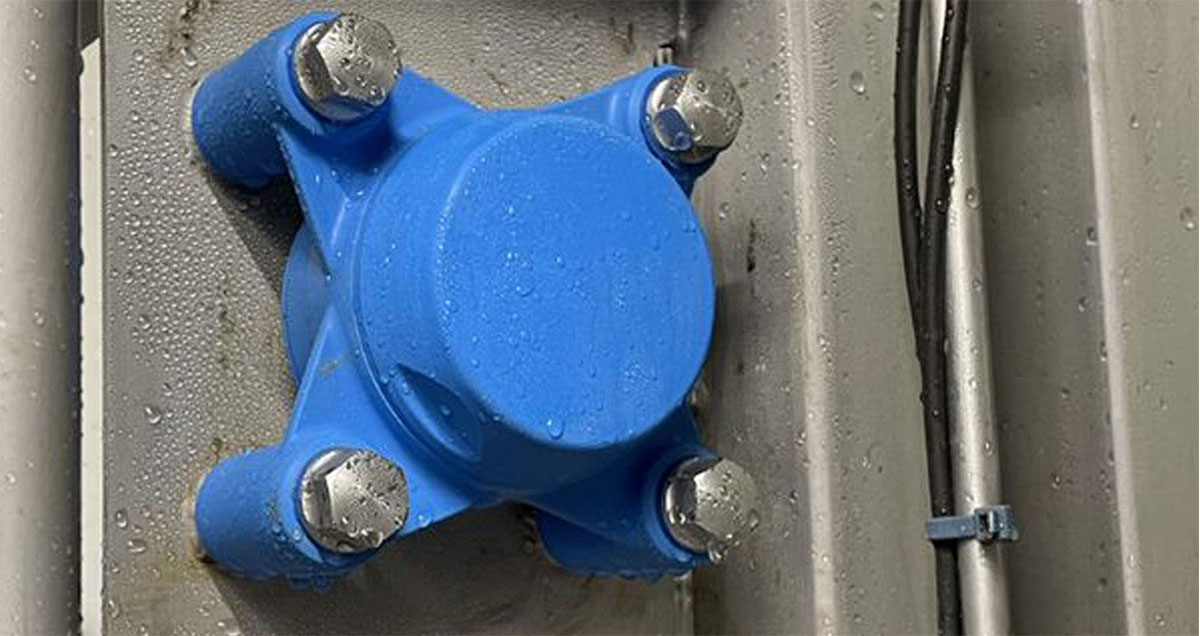

In food-grade machinery, the bearing housing is often overlooked - but it plays a critical role in hygiene, durability, and uptime. Selecting the wrong type can lead to contamination risks, frequent maintenance, and costly downtime. At NGI, we specialize in hygienic bearing housings engineered for washdown environments and certified to EHEDG, USDA, and 3-A standards.

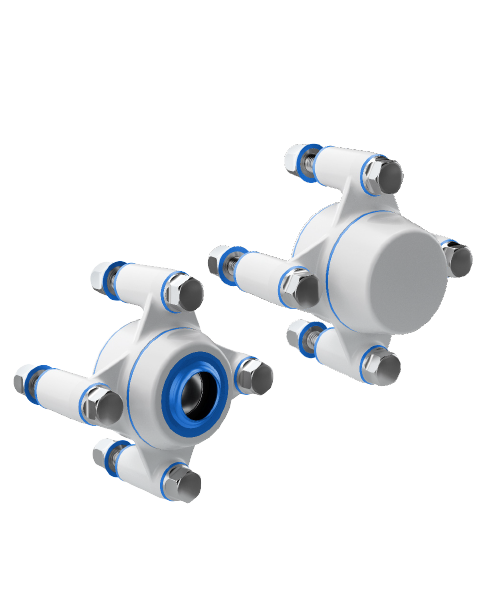

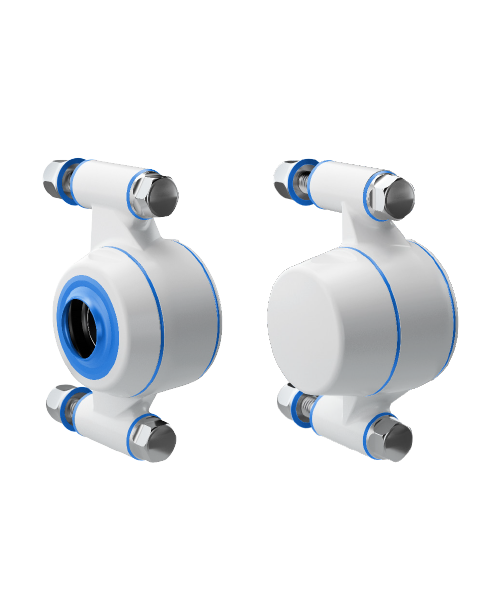

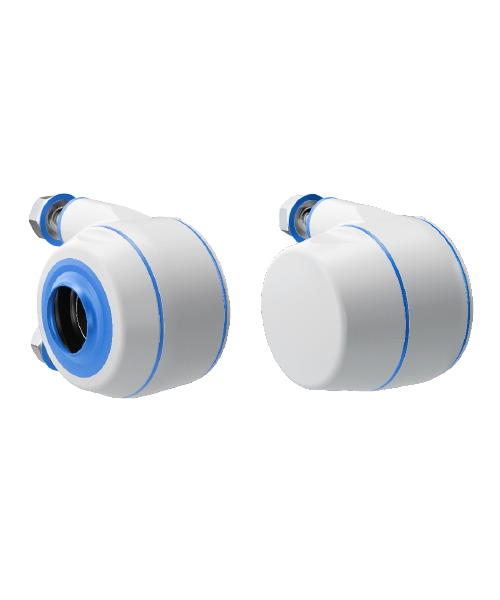

This guide compares five core housing types—ranging from compact 2-bolt blocks to heavy-duty 4-bolt and threaded flange variants- so you can choose the best fit for your application. Whether you're upgrading a conveyor or designing a new vertical auger, understanding these options helps you build smarter, cleaner, and more reliable equipment.

Written by Austin Davis, Category Manager, NGI