Hygienic and automatized cleaning of conveyor belts

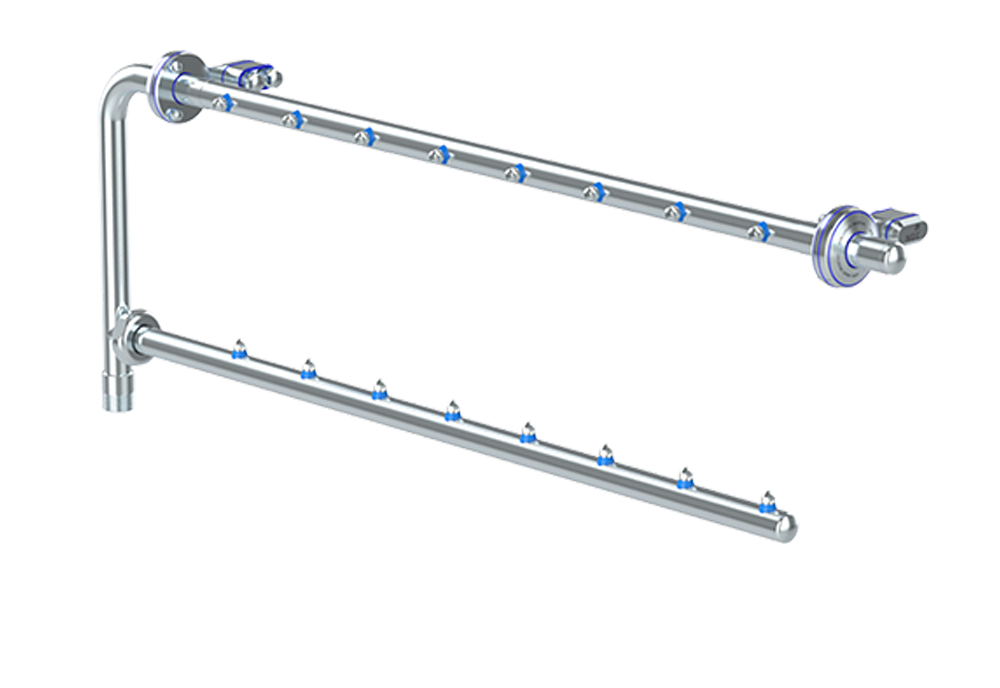

Clean-in-Place (CIP) unit is a piece of state-of-the-art hygienic design. It’s inspired by EHEDG, USDA, and 3-A design guidelines.

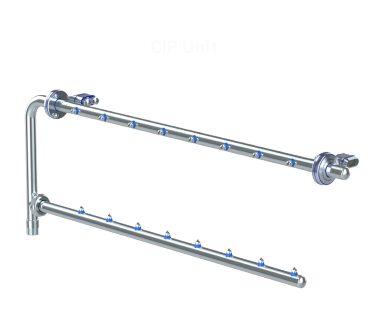

Furthermore, it is easy to install as it is compatible with all standard conveyor belts. We have three different mounting fasteners all depending on whether the CIP unit is to be mounted on a square, a square angled, or a round tube.

When installed, you prevent contamination and microbial growth. You simply increase your hygiene level. The CIP Unit has angular adjustability of both bars.

CIP units play a vital role in upholding strict hygiene standards within the food processing industry. These units automate the cleaning process, ensuring that every part of your equipment is thoroughly sanitized. This consistent and reliable cleaning routine is essential for preventing contamination, maintaining food safety, and meeting industry hygiene regulations.

Manual cleaning can be time-consuming and labor-intensive. However, CIP systems streamline the cleaning process, significantly reducing downtime. With CIP, your equipment is cleaned faster and more efficiently, allowing for increased productivity in food processing. This improvement in operational efficiency translates to overall productivity gains.

Although the initial investment in a CIP system may appear high, it proves to be cost-effective in the long run. By reducing water, chemical, and labor costs, automated cleaning minimizes waste and lowers utility bills. Additionally, the reduced need for manual labor enables your workforce to focus on other critical tasks, further enhancing operational efficiency.

Regular and thorough cleaning provided by CIP units helps maintain your equipment in optimal condition. By preventing the buildup of residues and corrosive elements, CIP systems extend the lifespan of your equipment, reducing the frequency of repairs and replacements.

Investing in a CIP unit is a strategic decision for any food processing facility aiming to improve hygiene, efficiency, and compliance while minimizing costs and equipment wear and tear. It is an investment that yields dividends in terms of safety, productivity, and long-term savings.

Please do not hesitate to contact us if you have any questions regarding the different options available, pricing details, or delivery timelines.