Far more than just a supplier

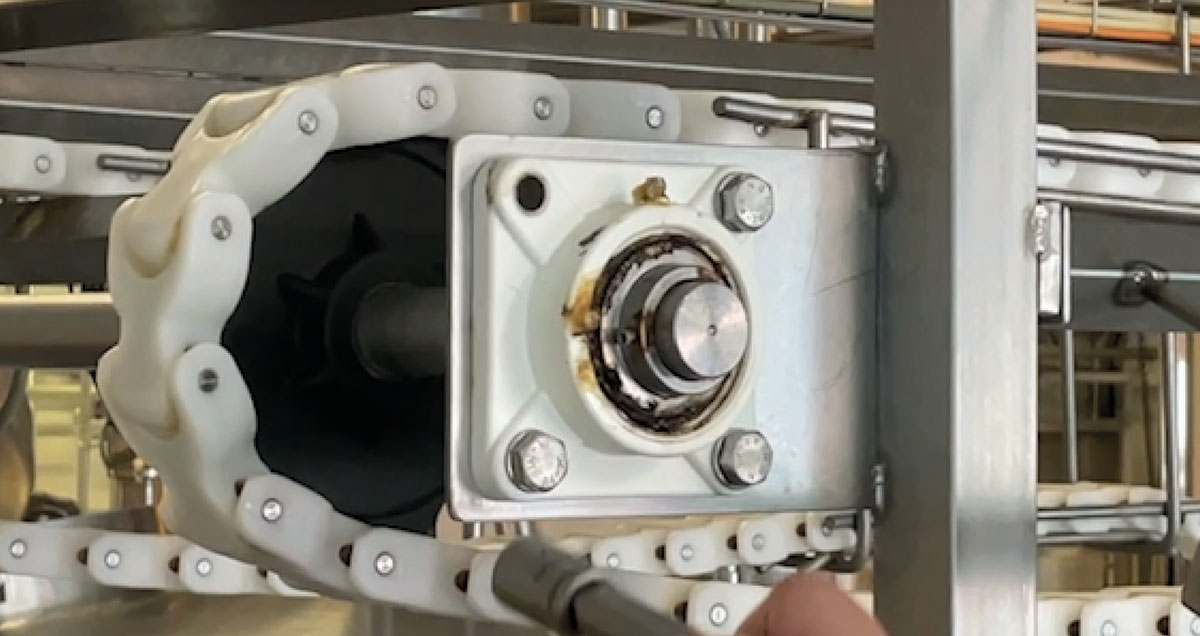

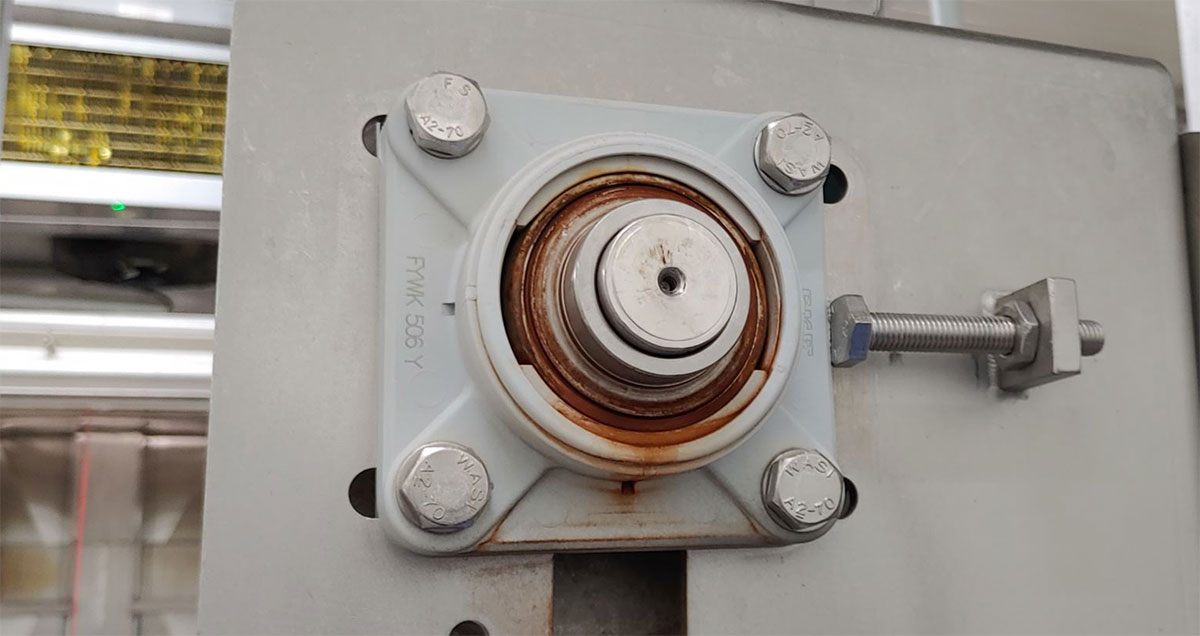

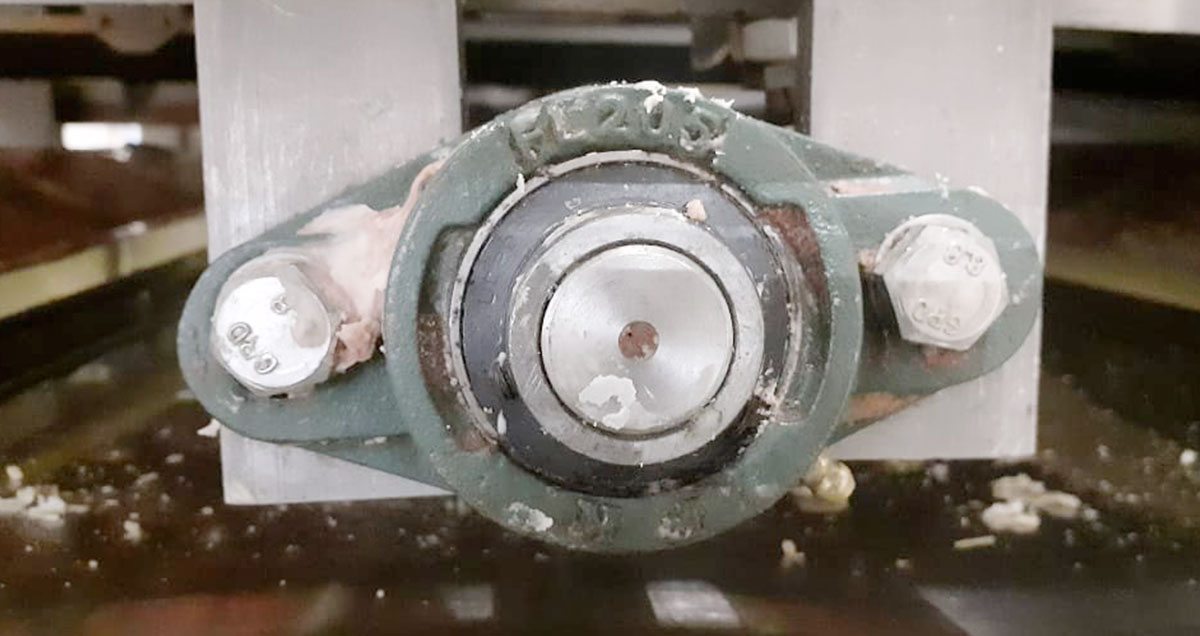

It is crucial that the top management of any company relates to the real risks associated with hygiene

Delivering quality products on time and at a fair price is not sufficient to be a successful, modern B2B company.

You must always build your collaborative relationships with an authentic intention to create real value for your business partners.

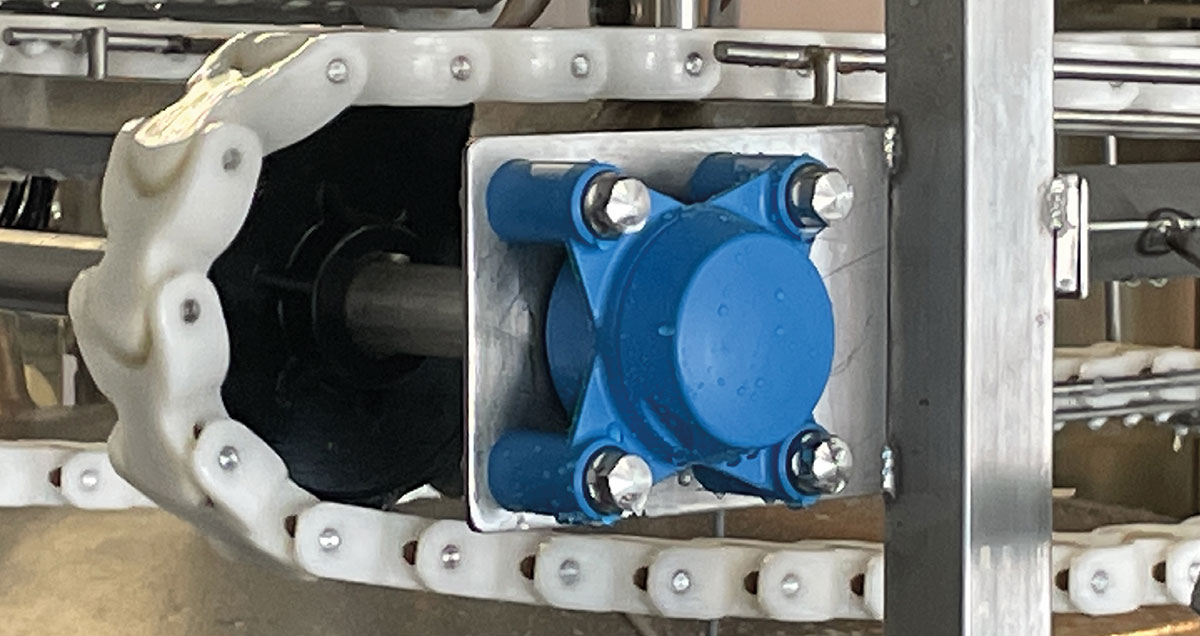

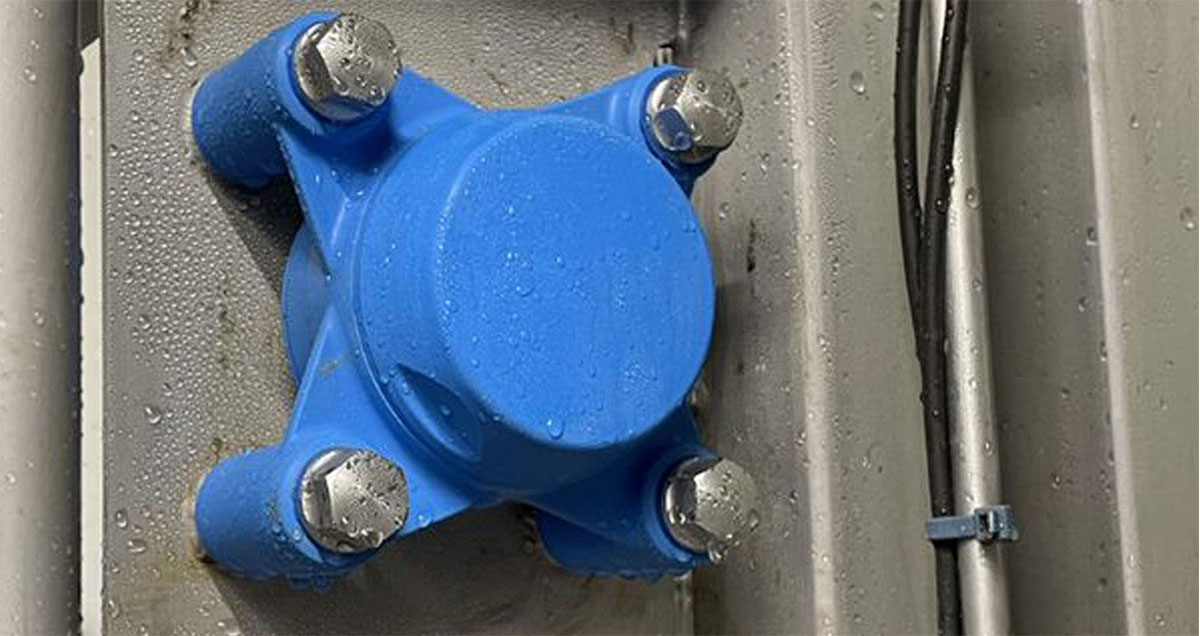

Hygienic components and solutions are at the heart of everything we do and everything we believe in.

It is crucial that the top management of any company relates to the real risks associated with hygiene, and that the management ensures that the company acts in a way that is in line with the risks.

When you choose NGI you do not just get a reliable product supplier - you get a value-adding partner that contributes to improving your competitiveness through continuous innovation and knowledge-sharing initiatives.