Innovative and patented hygienic design

We always strive for the highest standard of excellence in our product development

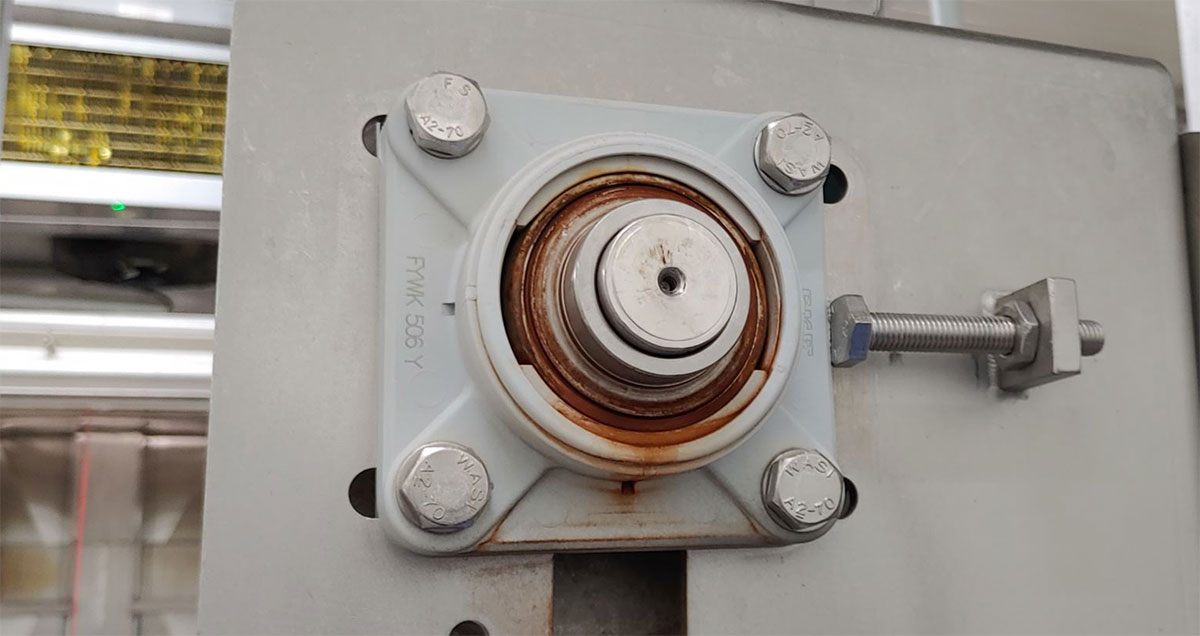

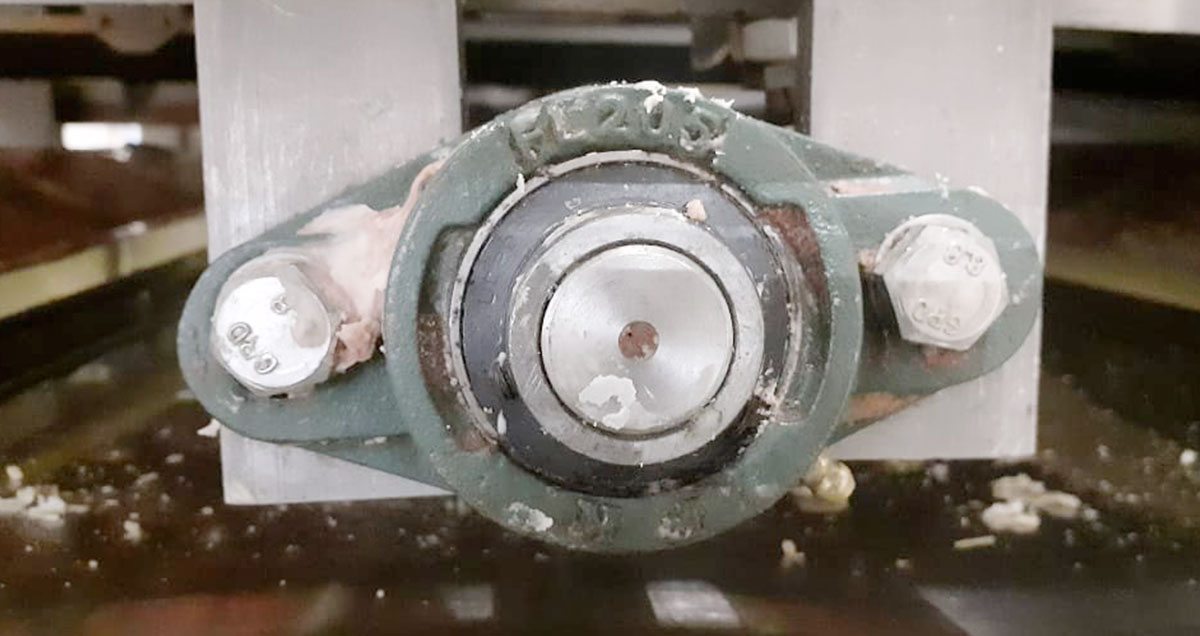

We always focus not only on the fundamental requirements such as stability under load, vibration absorption capacity, and the ability to fix the foot onto the floor - but also on the importance of sealing moveable parts, adjustability without exposing the threads, absence of unnecessary corners and edges, and the best possible design for facilitating cleaning.

The hygienic bearing houses from NGI are the only bearing houses in the world certified by USDA, EHEDG, and 3-A standards.

The hygienic castors are the only patented castors in the world following USDA, EHEDG, and 3-A design principles. Both products are designed for quick and easy installation as a plug n-play solution that can simply substitute current unhygienic components.