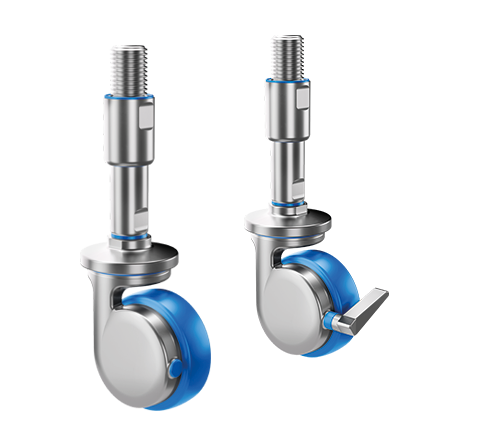

Stop Cross-Contamination at the Source with Hygienic Casters

Casters are often overlooked - but they can hide serious hygiene risks. Poor design in components like castors, belts, and drum motors can lead to cross-contamination, product recalls, and costly downtime.

If you build machines, this risk is closer than you think. Many end-users struggle with hygiene issues - even on new equipment - without realizing it.

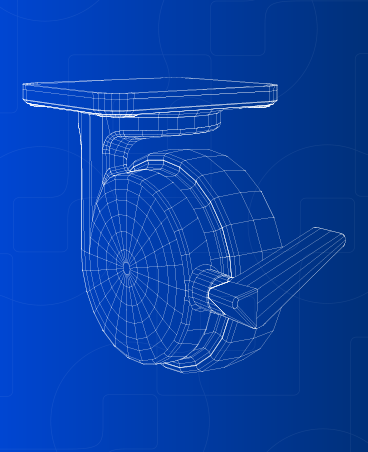

See the risk. Solve the Risk. Upgrading to hygienic design isn’t just about compliance; it’s about protecting your customers and staying competitive.

We tested our new hygienic casters against standard models - and the difference is clear. Casters are critical to your production line, but notoriously hard to clean. Watch the test below and see the results for yourself!