Stop Carryback Before It Becomes a Risk

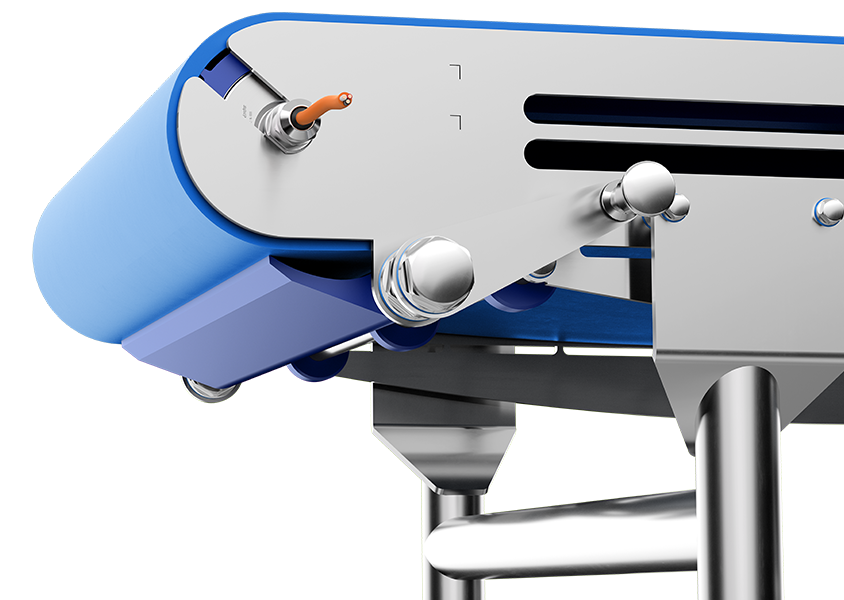

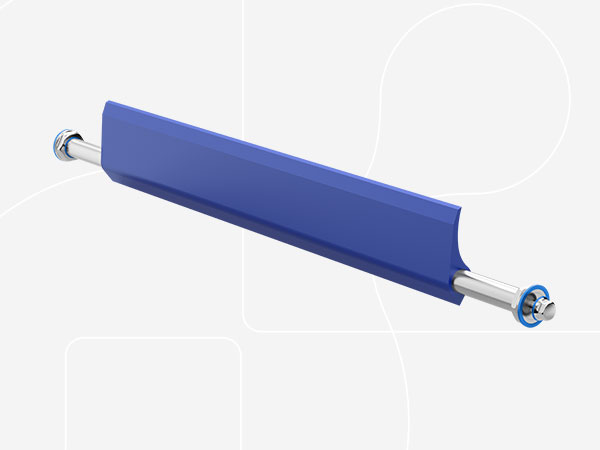

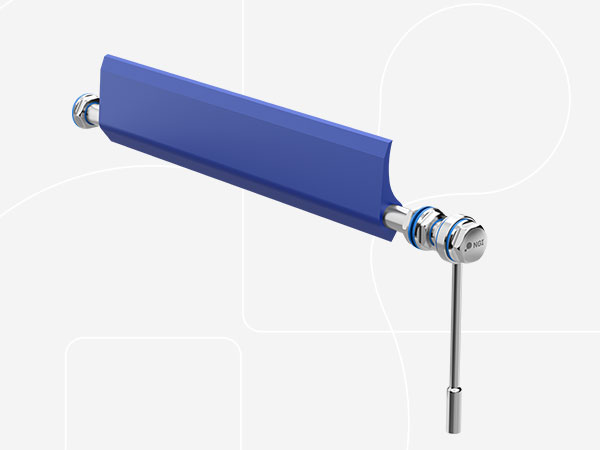

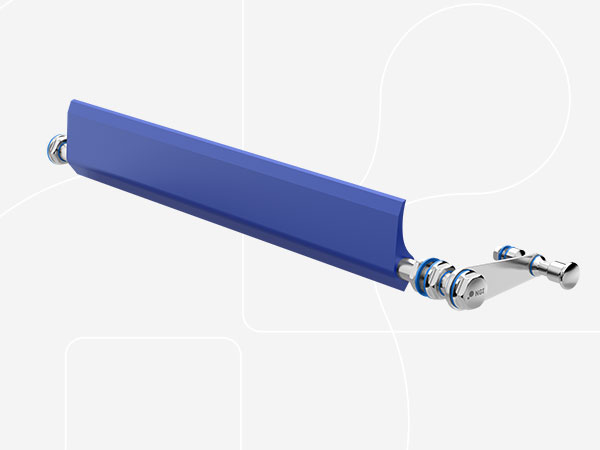

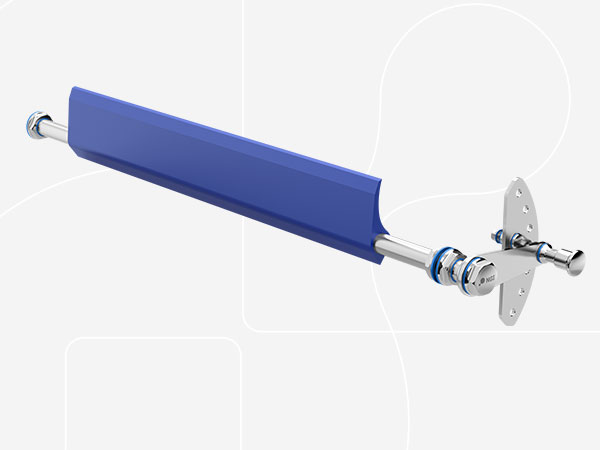

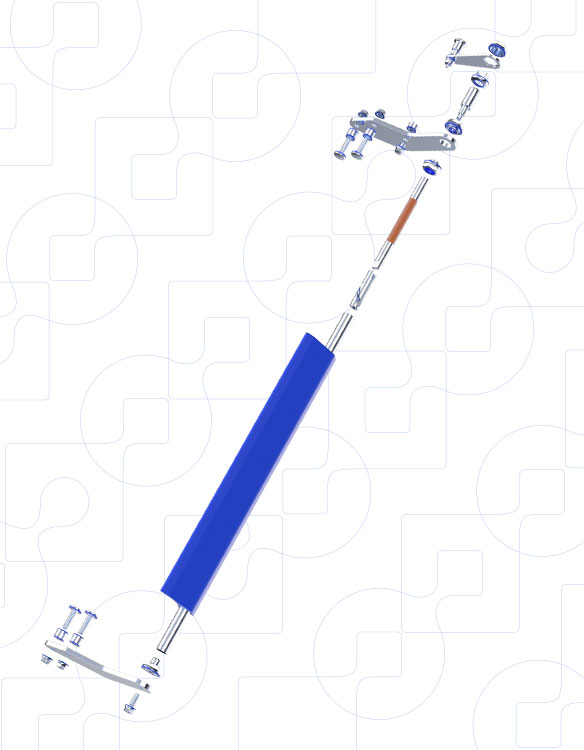

From carryback prevention to effortless maintenance, our hygienic scrapers offer a quick‑release mechanism for fast belt access—ensuring a cleaner, safer, and more efficient production line.

If you build or maintain food‑processing lines, that risk is sitting on your belts. Even new systems can struggle when cleaning takes too long or leaves blind spots.

See the risk. Solve the Risk. Our scraper delivers full‑width cleaning coverage, reduced carryback, and precise pressure adjustment.

Designed to support EHEDG and 3‑A principles, it helps you keep hygiene under control and downtime to a minimum.