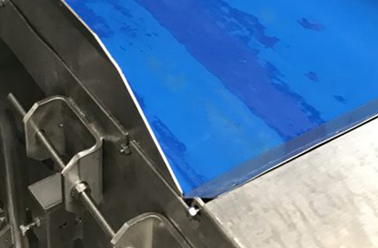

Improved food safety and lower energy consumption

Using our synchronous oil-free drum motors offers several advantages over asynchronous drum motors for food processing companies

Synchronous oil-free drum motors typically have a longer lifespan and require less maintenance compared to asynchronous motors. They eliminate the need for oil changes and reduce the risk of downtime due to maintenance activities.

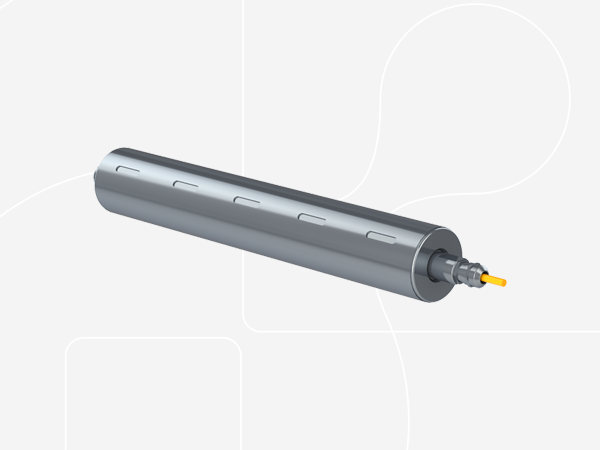

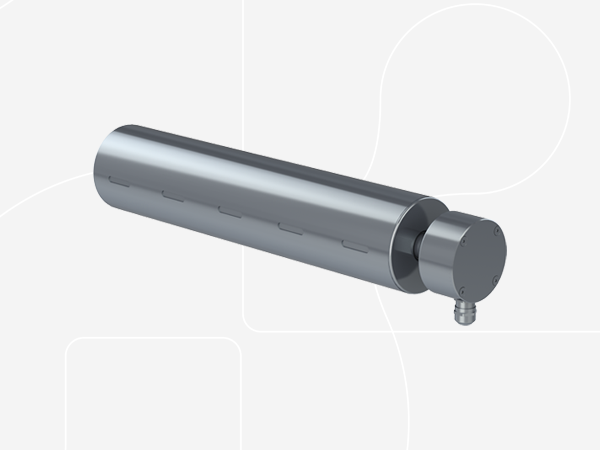

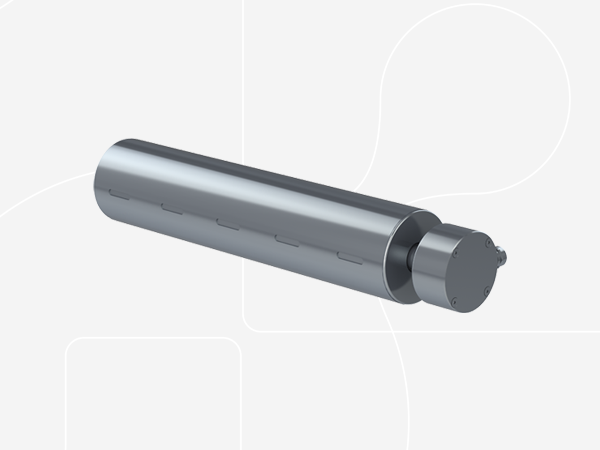

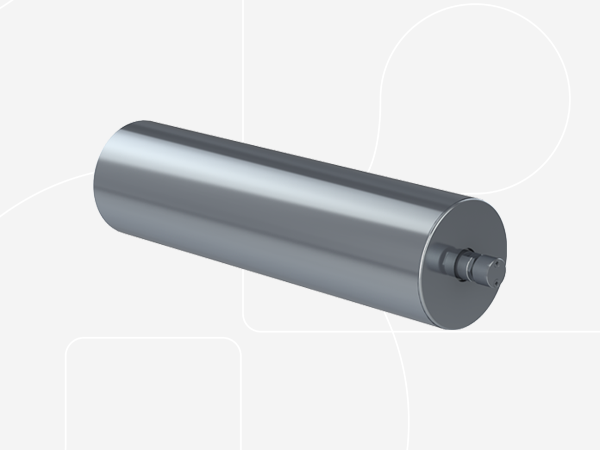

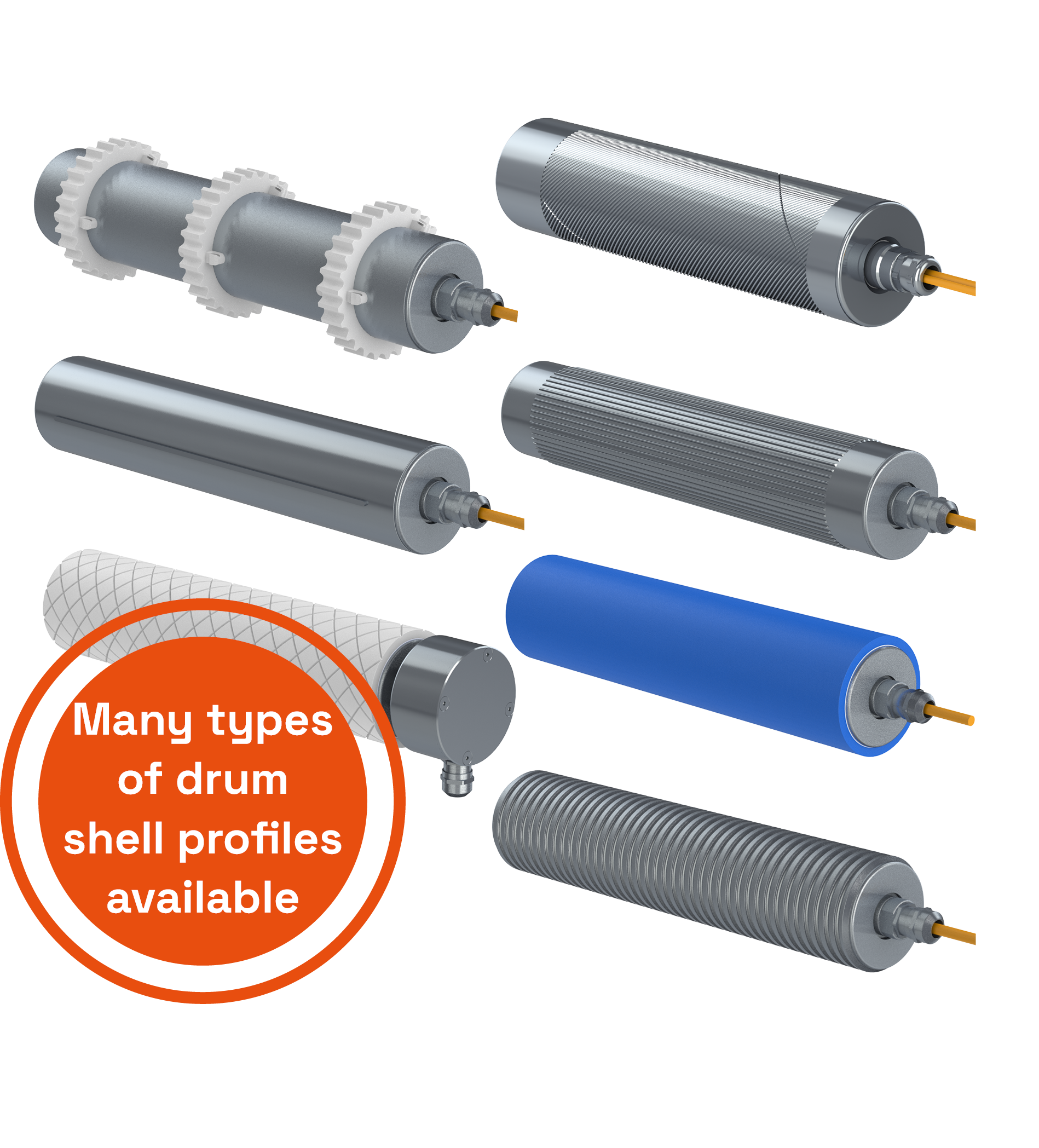

Please find additional information below and explore our diverse range of models.