Hygienically Optimized Leveling Casters - Overview of Groups and Features

Explore our versatile selection of hygienically optimized leveling casters, designed to meet the highest standards of cleanliness and functionality in production environments.

With a wide range of mounting options and a load capacity of up to 200kg, we can address your specific challenges and ensure smooth, efficient operations.

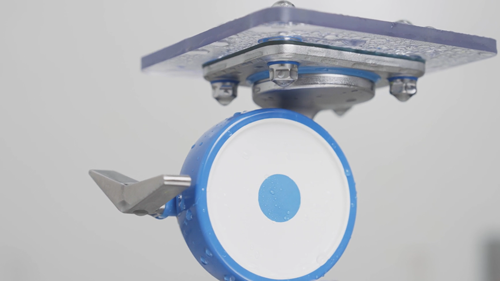

- Material and Sizes: The caster wheel is crafted from white polyamide, and the blue tread is made from polyurethane. All sealings are made with FDA-approved TPE. These casters are available in wheel dimension Ø100 and are constructed from high-quality stainless steel AISI 304/A2 (1.4301).

- Construction Details: Our casters are designed with a one-sided fork body that facilitates easy cleaning, thereby enhancing hygiene in production environments. Constructed from durable and corrosion-resistant stainless steel, the body is built to last. Each caster has two high-quality stainless steel ball bearings for smooth operation. Moreover, these casters comply with DS/EN 12532:1999 & DS/EN 12527:1999 standards, ensuring they meet industry regulations and deliver high-quality performance.

- Ease of Installation: With a wide range of mounting possibilities the casters are designed to fit your needs.

Expand the following paragraph to discover a precise overview of each of our product categories along with direct access to them.

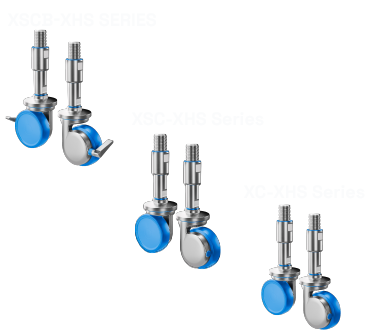

Product Variants:

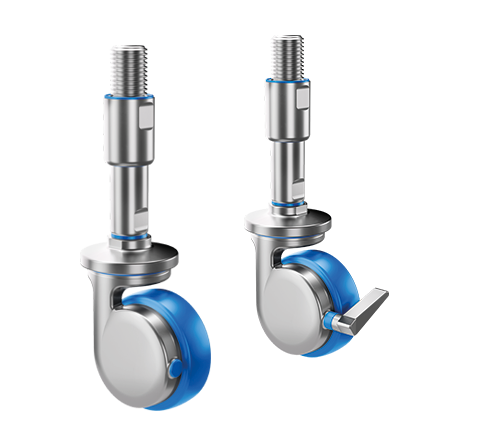

These adjustable casters come in both metric and imperial sizes, ranging from M24 to M36 (1” & 1 ¼”). Available in both long and short variants, they feature a sleeve that covers the threads to meet stringent hygiene requirements.

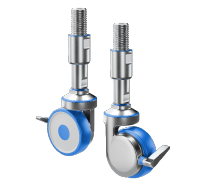

- XSC Series: The hygienic caster with levelling spindle of customers' choice with swivel, but without brake

- XSCB Series: The hygienic caster with leveling spindle of customers choice - Similar to the XSC but includes a wheel and swivel lock.

- XC Series: The hygienic caster with leveling spindle of customers' choice - Similar to the XSC but a fixed caster.

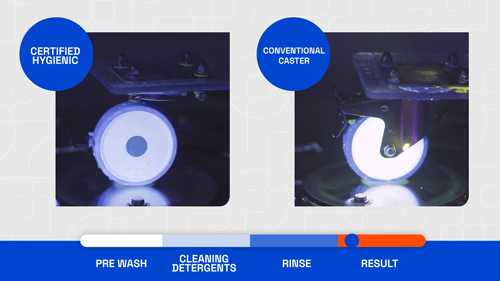

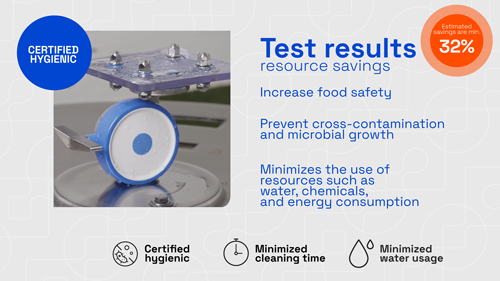

Test by Force Technology - Hygienic casters versus standard casters

In addition to customer testing, our new casters have been tested against standard casters by FORCE Technology - the Danish Research and Technology Organization of Hygienic Design.

These tests highlight the significant savings in resources and the enhanced food safety provided by our casters. Watch the short video below!

Test in a production facility - Hygienic casters versus standard casters

Also find a video where you can see a test with one of our customers, where we have tested our hygienic casters against the existing casters currently in operation. The benefits were clear. These tests illustrated the quantity of debris that casters accumulate from the production floor while in use. Please view the brief video below.

For more information or assistance, please reach out to us.

Read moreRead less