Hygienic Product Line: Hygienic CIP Unit

The CIP Unit is a convenient plug-and-play solution for cleaning belting equipment in the food industry, enhancing the efficiency and eco-friendliness of the cleaning process.

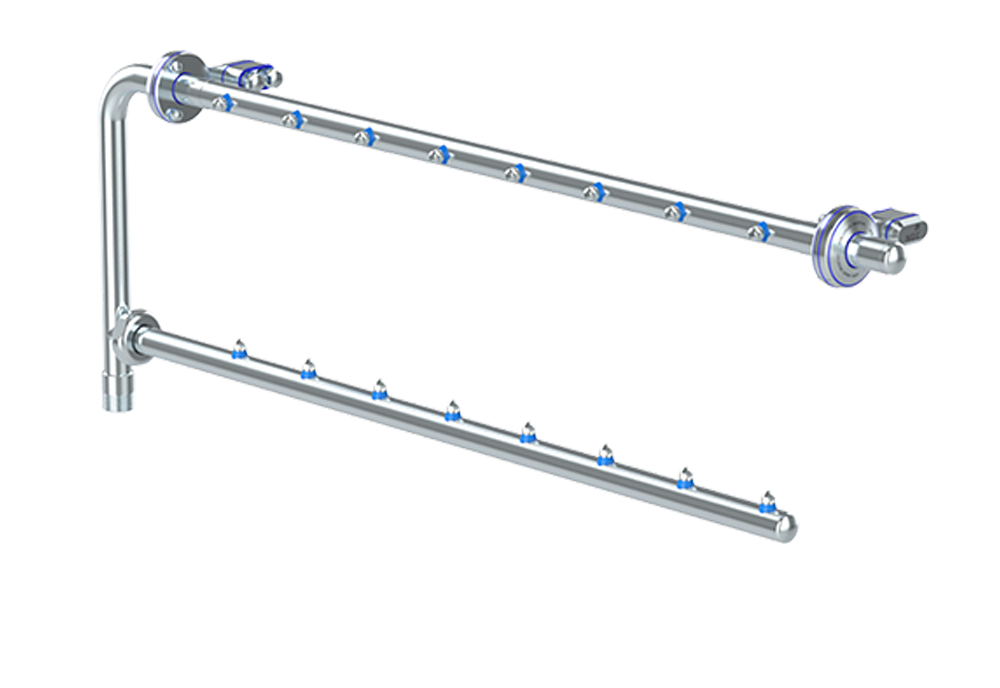

The CIP unit offers a straightforward yet effective approach, with nozzles positioned on the bar to spray the conveyor belt's front and back between production cycles.