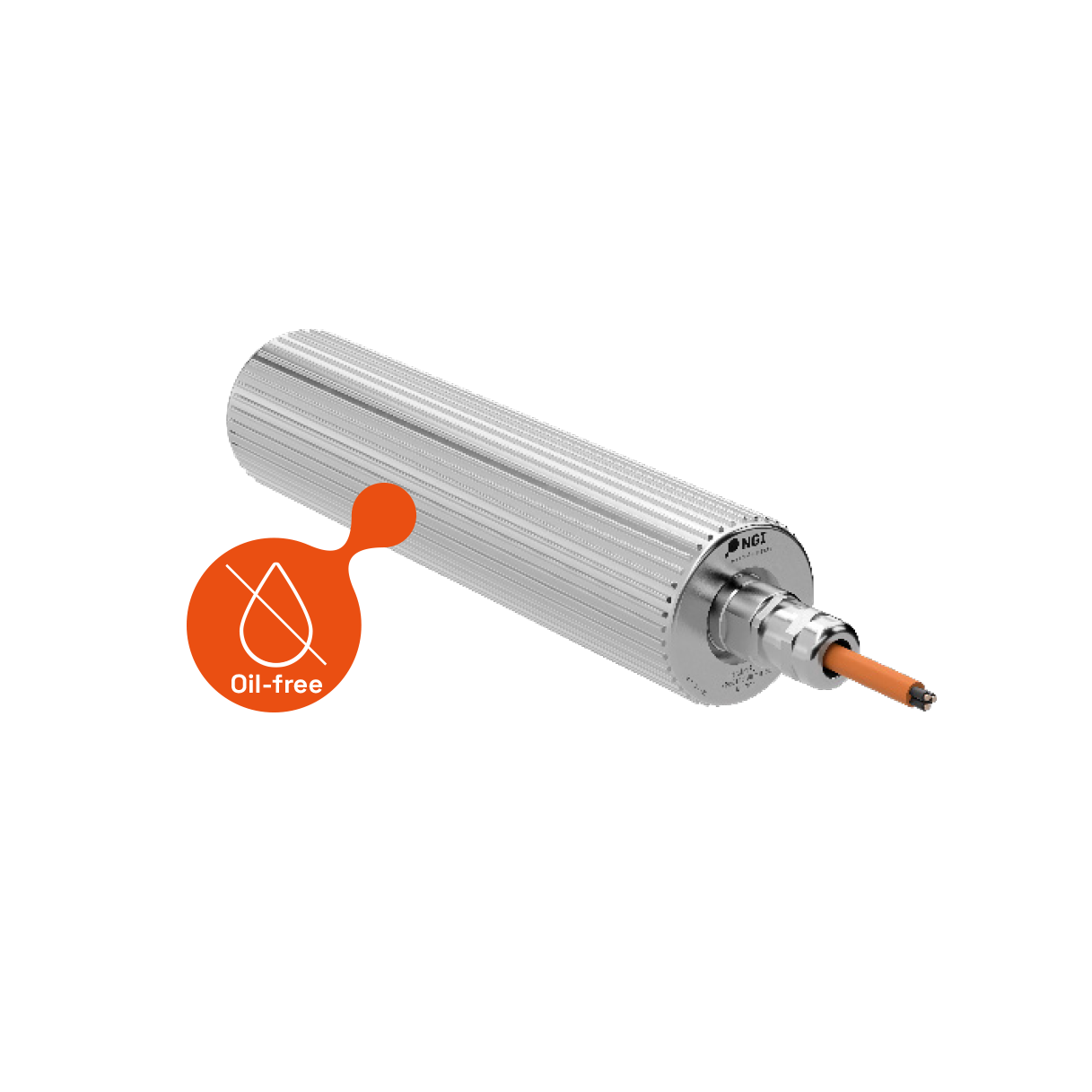

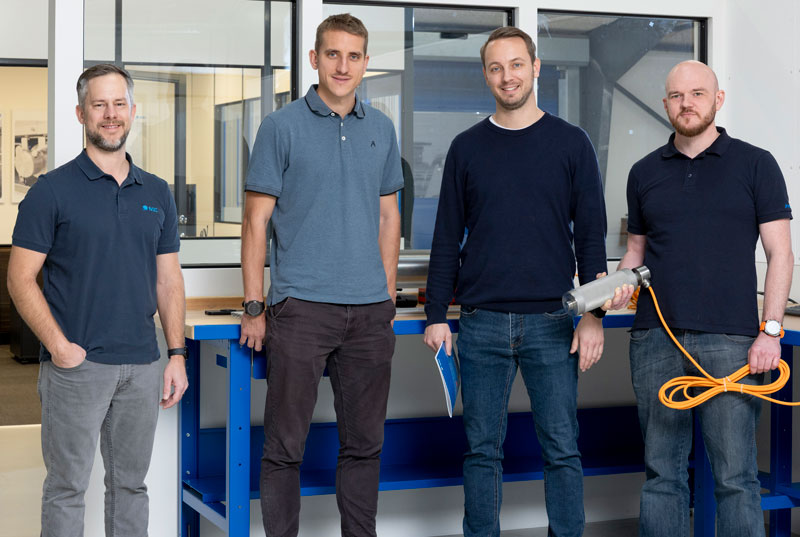

Support That Stands Out.

Our Application Engineering Team works with you to ensure the MTS62 is configured for your exact machine, application, and production flow.

While others only ask for specs like power and width, we dig deeper—tension, load, usage patterns—because the right setup starts with the right understanding.

And we make the process easy. You’ll save time, prevent costly missteps, and get a tailored drive solution that just works.