Alco food-machines

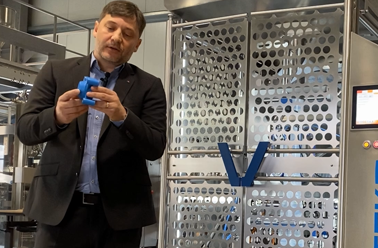

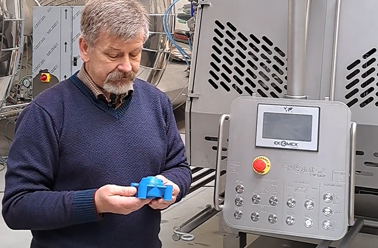

Watch a video from Alco food-machines, which explains how a component on a food processing machine can influence your competitiveness.

Choosing a triple-certified hygienic component ensures that the foundation of your production equipment complies with the strictest demands for hygiene, environmental impact, and durability.

The hygienic standard of your production equipment is a crucial competitive parameter when it comes to winning an order or being authorized as a new supplier.