Highlights from VELTEKO's testimonial includes:

From the Ground Up: How Our Partnership Began

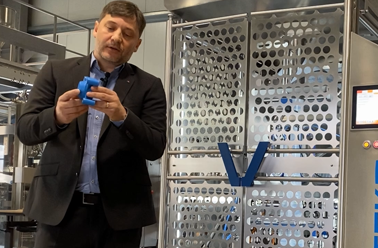

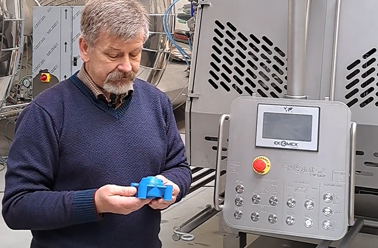

Our journey with NGI started from the ground—literally. Seven years ago, VELTEKO integrated NGI’s hygienic feet into our machines. As we pushed further into hygienic design, we expanded our collaboration in 2022 to include hygienic screws and bearings.

Why NGI? A Partnership Built on Excellence

- Unmatched Product Range: NGI offers a full stock of hygienic components, ensuring fast delivery when we need it.

- Certified for Safety: EHEDG and USDA certifications help us meet strict industry standards.

- Designed for Cleanability: IP69K-rated components ensure full washdown capability from every angle—top and bottom.

- Zero Maintenance: NGI’s bearings require no lubrication, reducing downtime and simplifying upkeep.

Beyond Food: Hygienic Design is the Future

While our machines primarily serve the food industry—handling meat, cheese, frozen goods, and even sauerkraut—the demand for hygienic design is expanding into unexpected industries like confectionery and pet food.

What’s Next? Expanding NGI Across Our Portfolio

Our washdown machines have set new standards, and now we’re taking NGI components beyond just one model. As we expand their use across our entire machine portfolio, our partnership with NGI will continue to grow—ensuring the highest standards in hygiene and performance.