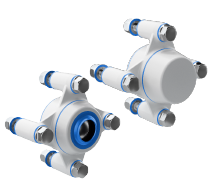

Hygienic Product Line:

Certified Bearing Houses

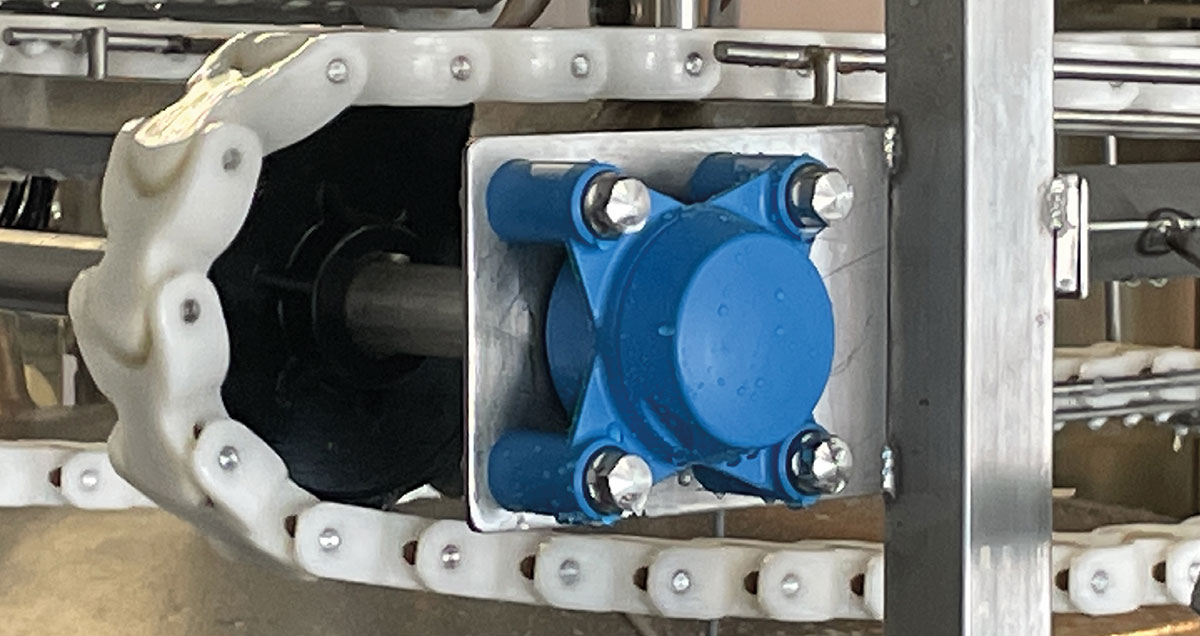

Raise the quality and hygienic standard of your processing equipment.

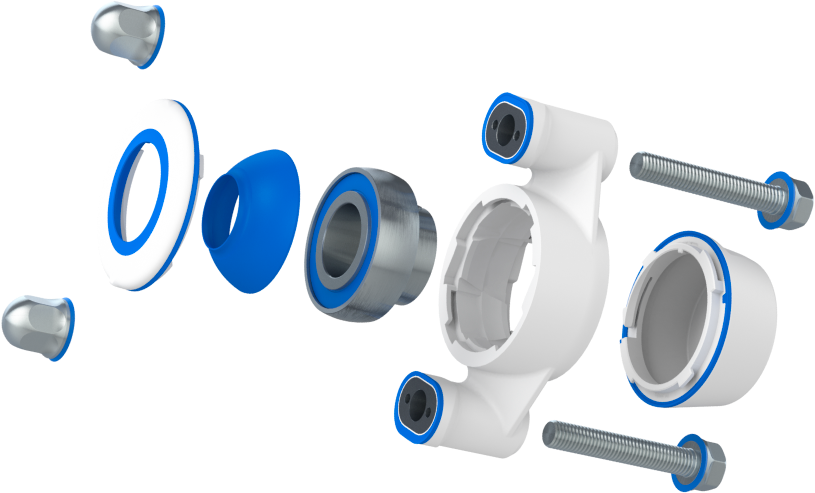

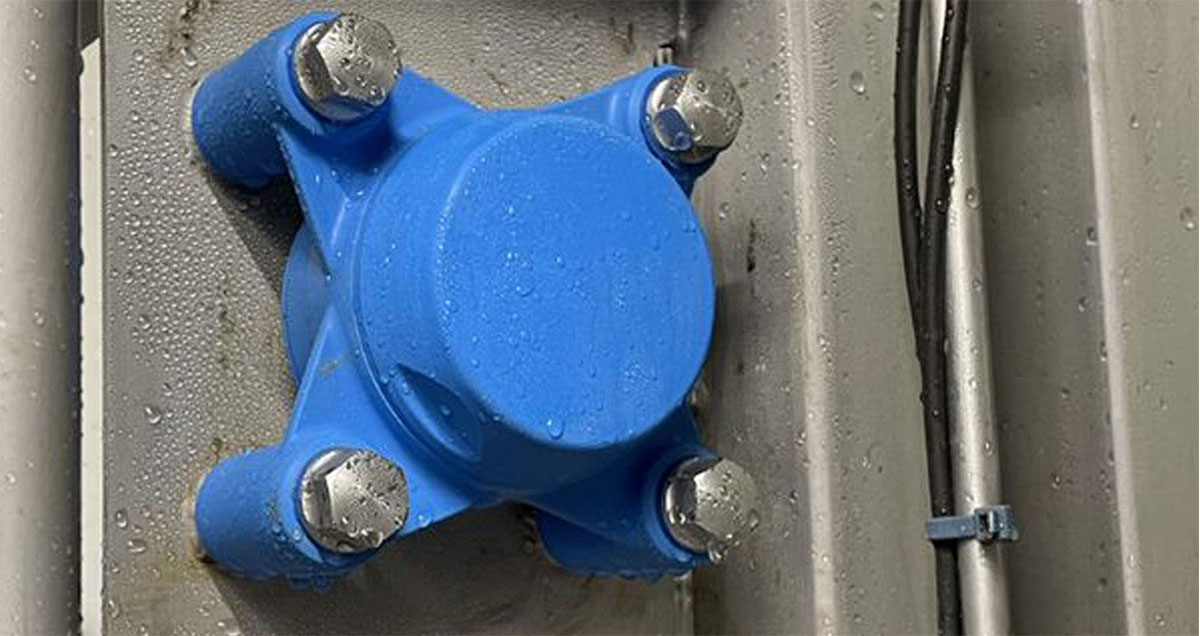

Our bearing houses are certified by EHEDG, 3-A and USDA - in addition to this, they are IP69K-certified. The bearings are lubricated for life resultning in both economic and environmental advantages. The product group consists of five different types of bearing houses and are designed according to ISO3228_2013

By selecting NGI bearing housings equipped with ceramic spherical ball bearings, you can achieve superior quality, durability, and stability.

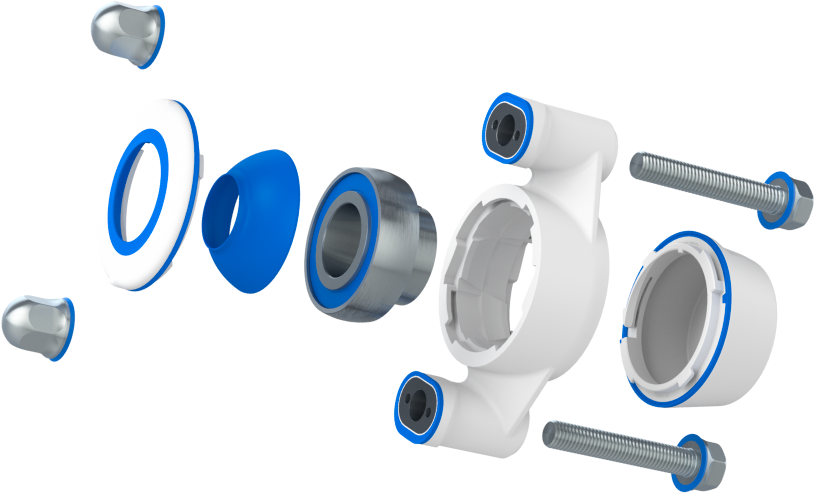

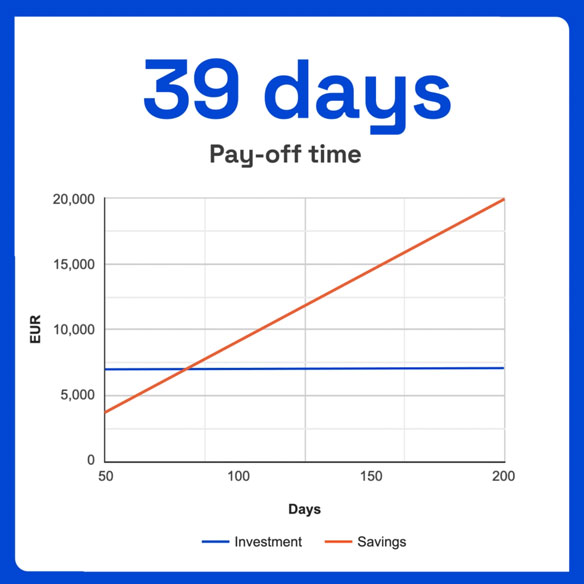

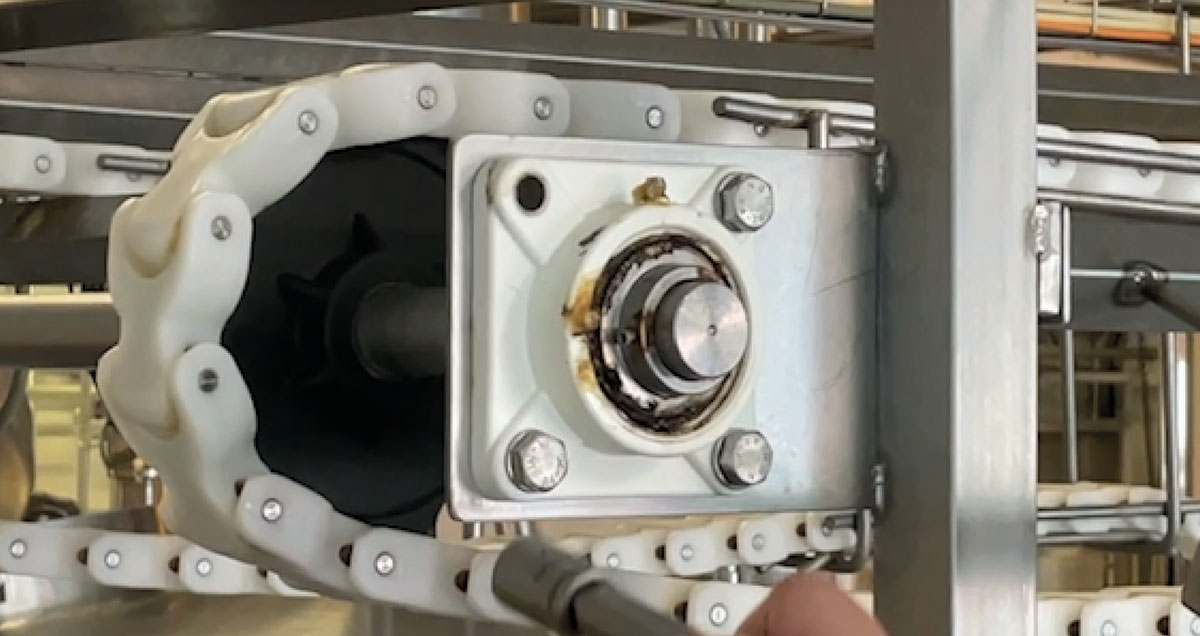

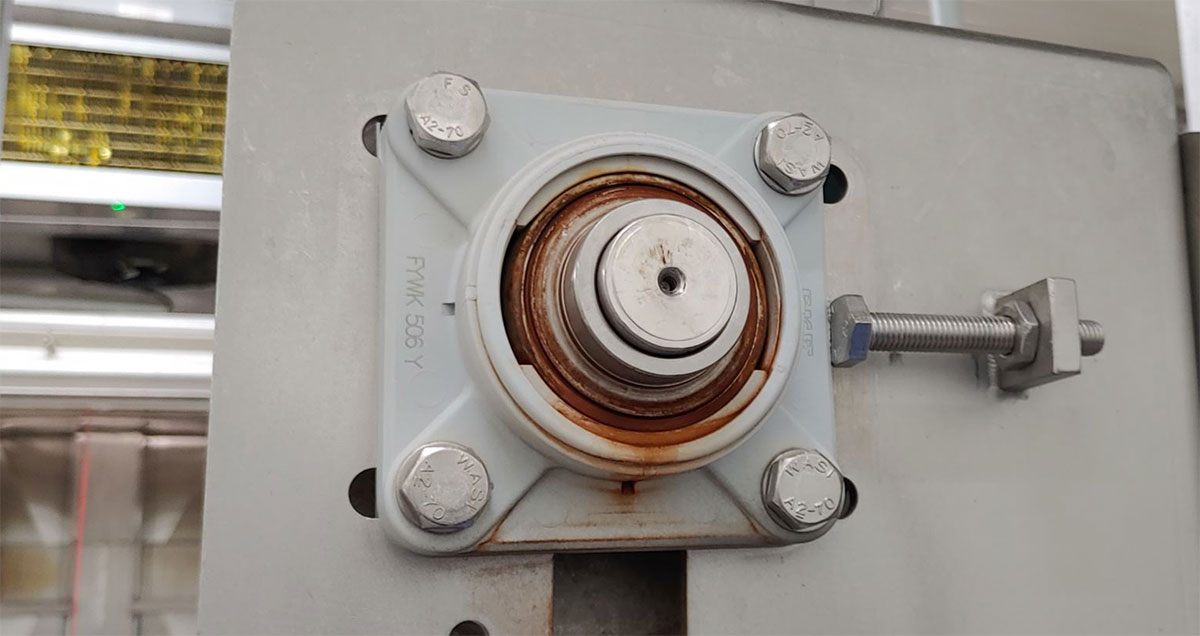

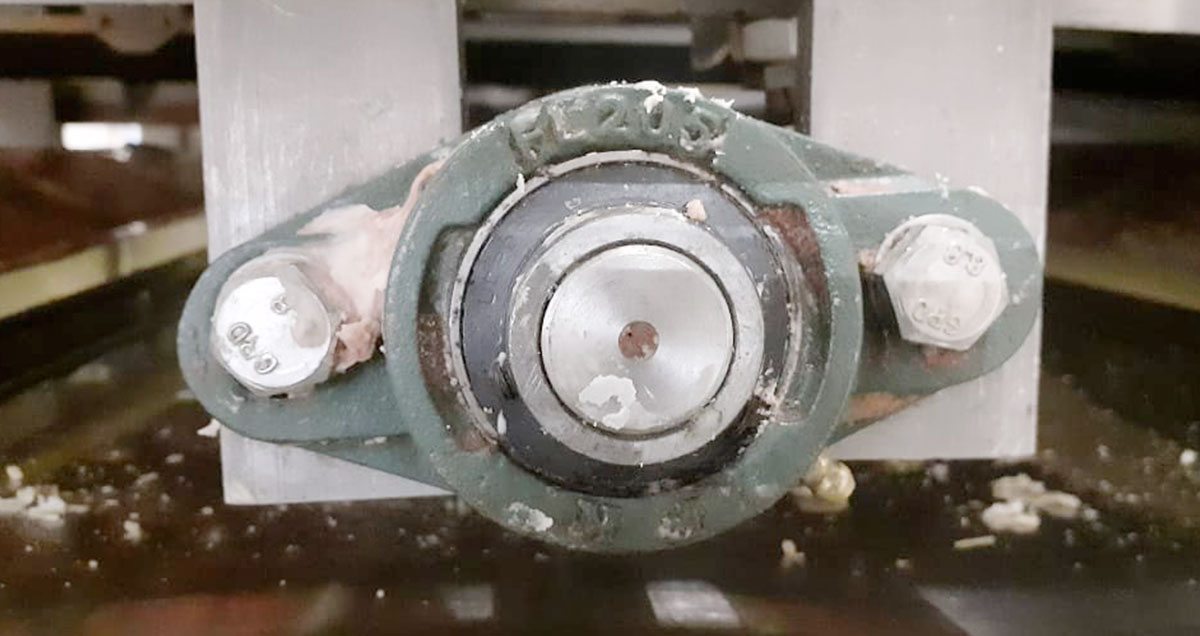

Bearings are often over-greased to block liquid out of the bearing house. This excess use of grease can create bacteria accumulation and compromise hygiene. The fact that the NGI bearing houses are lubricated for life does not only improve hygiene, it also saves resources, reduce costs and time spent on maintenance.

To ensure an EHEDG, 3-A, and USDA solution, our bolts and nuts are required for mounting. Furthermore, the USDA certification also requires the use of spacers.