Optimize efficiency and food safety with synchronous oil-free drum motors

Increase reliability, reduce operating costs, and simplify integration, while guaranteeing higher food safety!

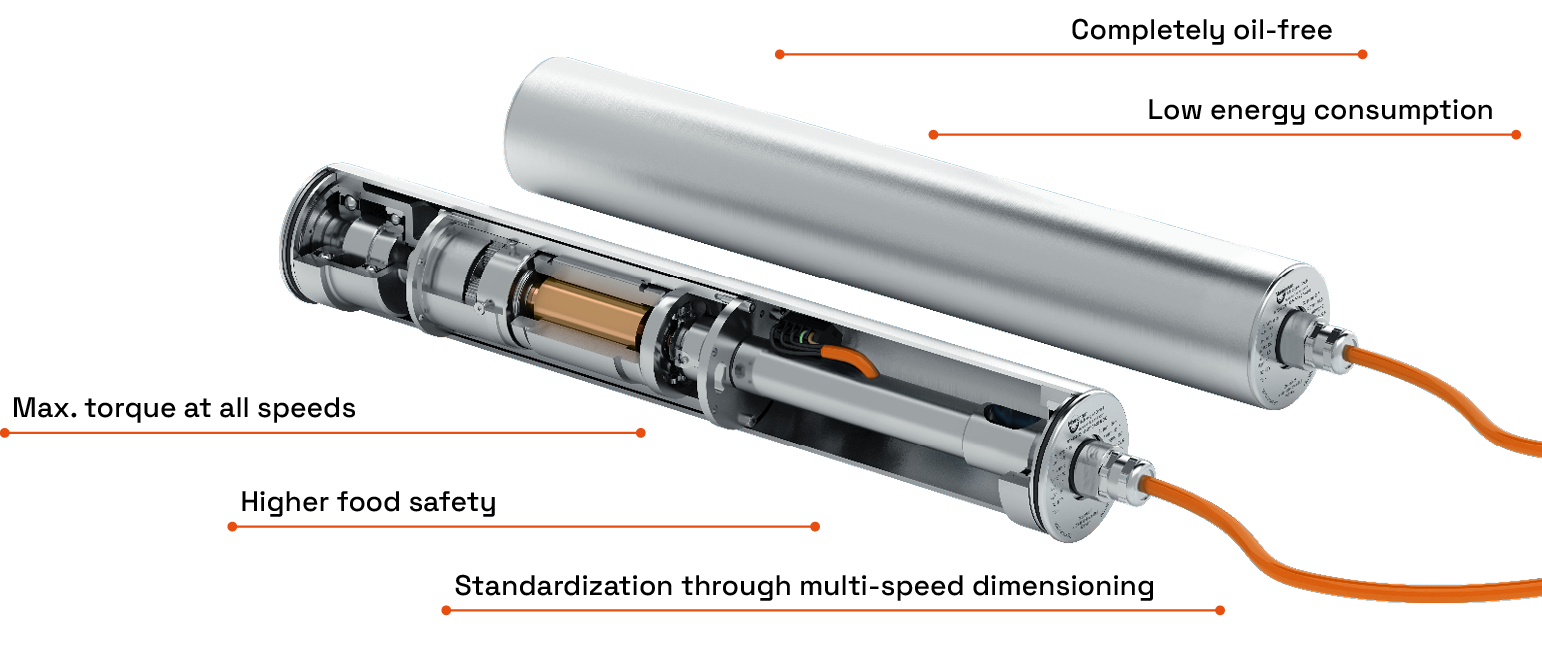

One of the major advantages of our drum motors is the technology itself, as a synchronous motor is used. Our synchronous conveyor drum motor runs completely without oil, guaranteeing higher food safety.

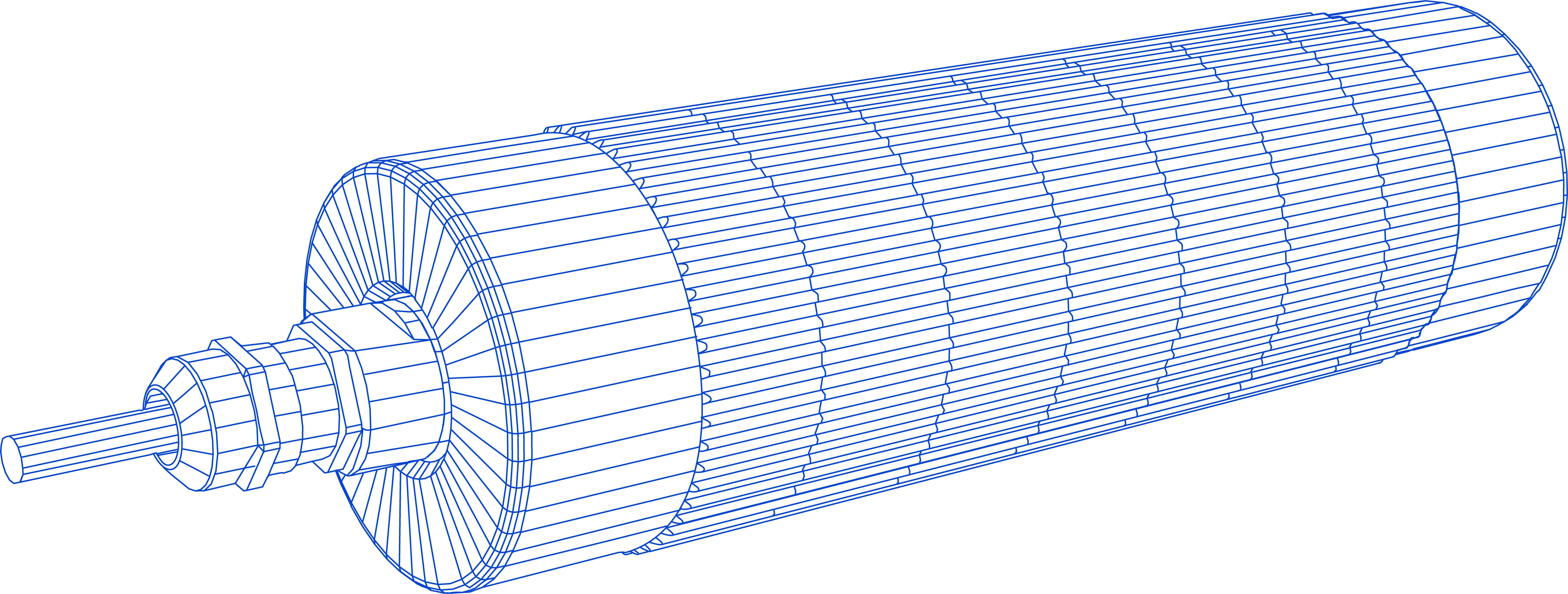

Our drum motor is space-saving, and an integrated component where all technology is protected inside the drum - the synchronous drum motors have a higher motor efficiency and thus less power loss.

This increases reliability, reduces operating costs simplifies integration, and guarantees higher food safety!

Our products are competent, yet simple to use. This promise is reflected in the very design of our products, which are carefully manufactured down to the smallest detail.