Certified Hygienic

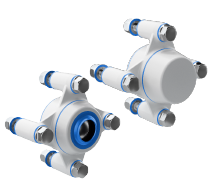

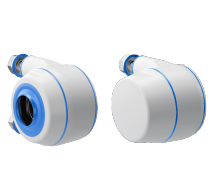

Bearing Houses

Good bearings deserve great houses

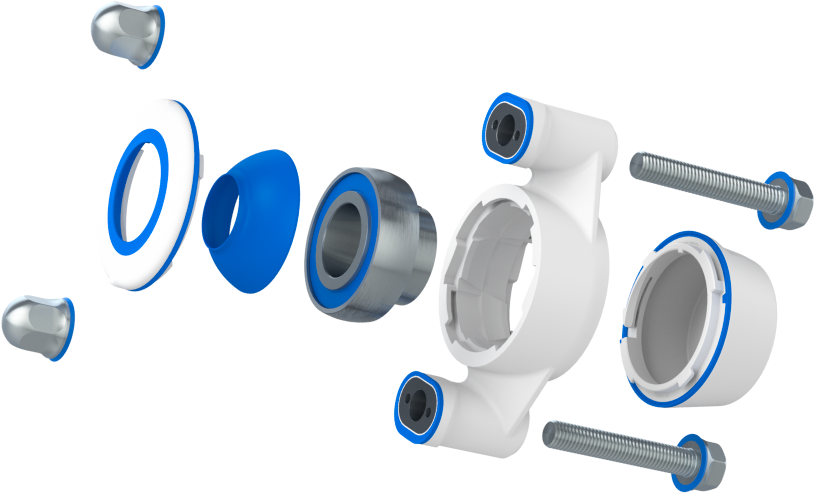

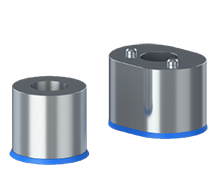

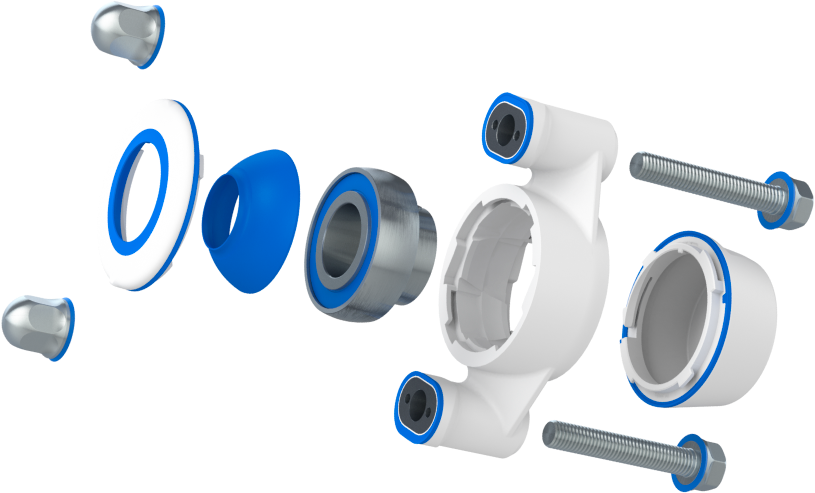

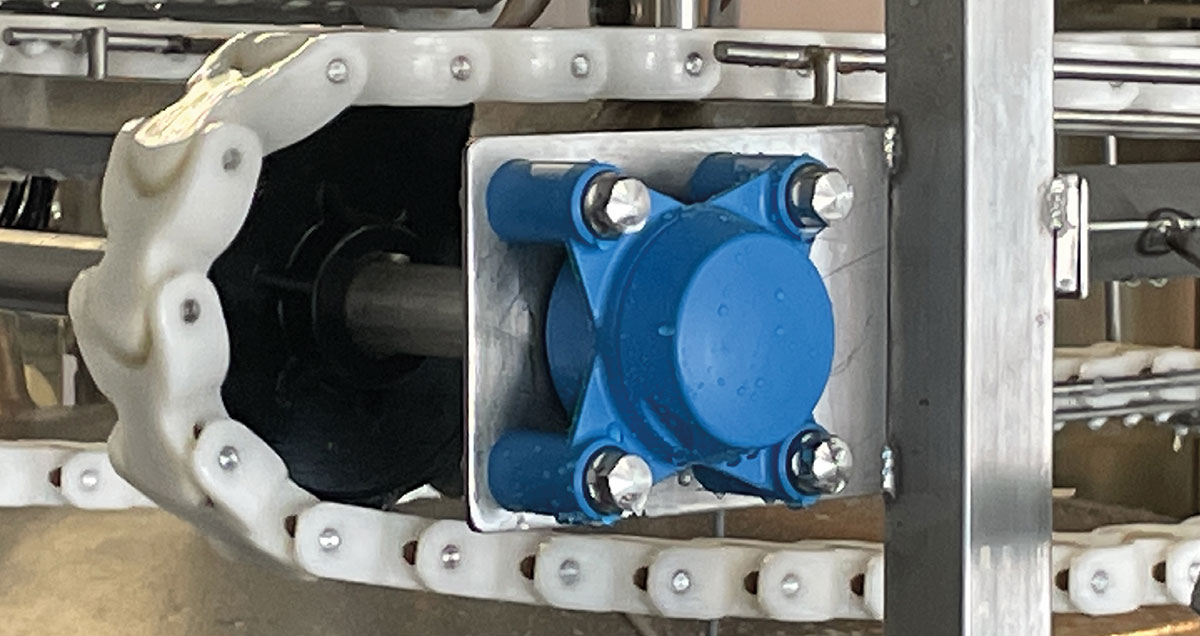

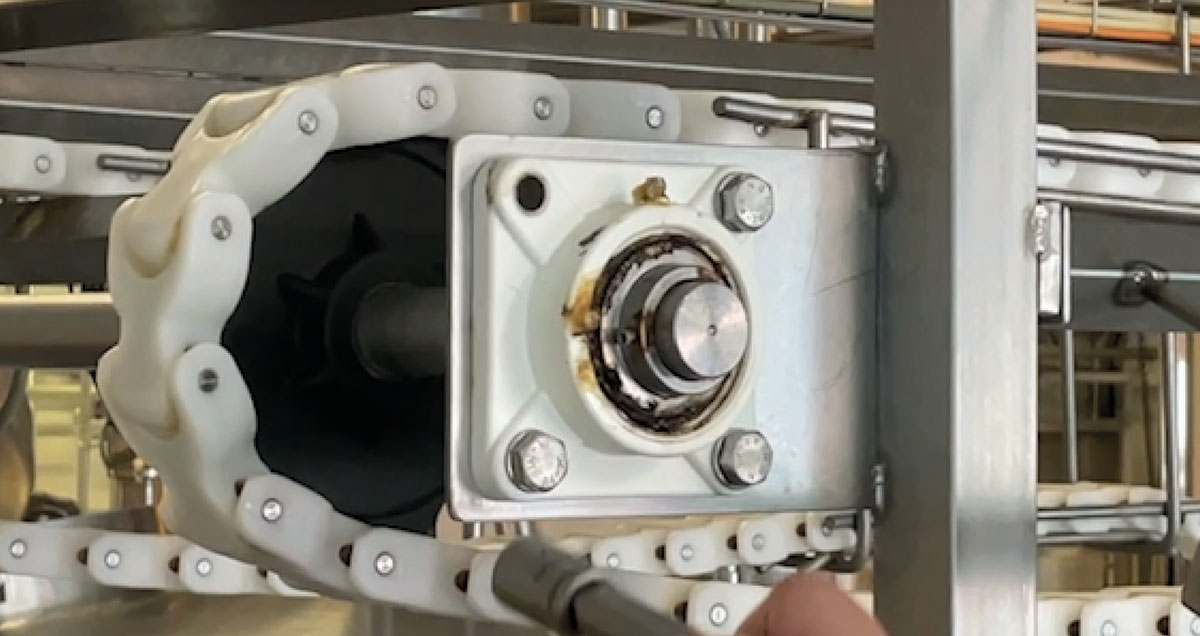

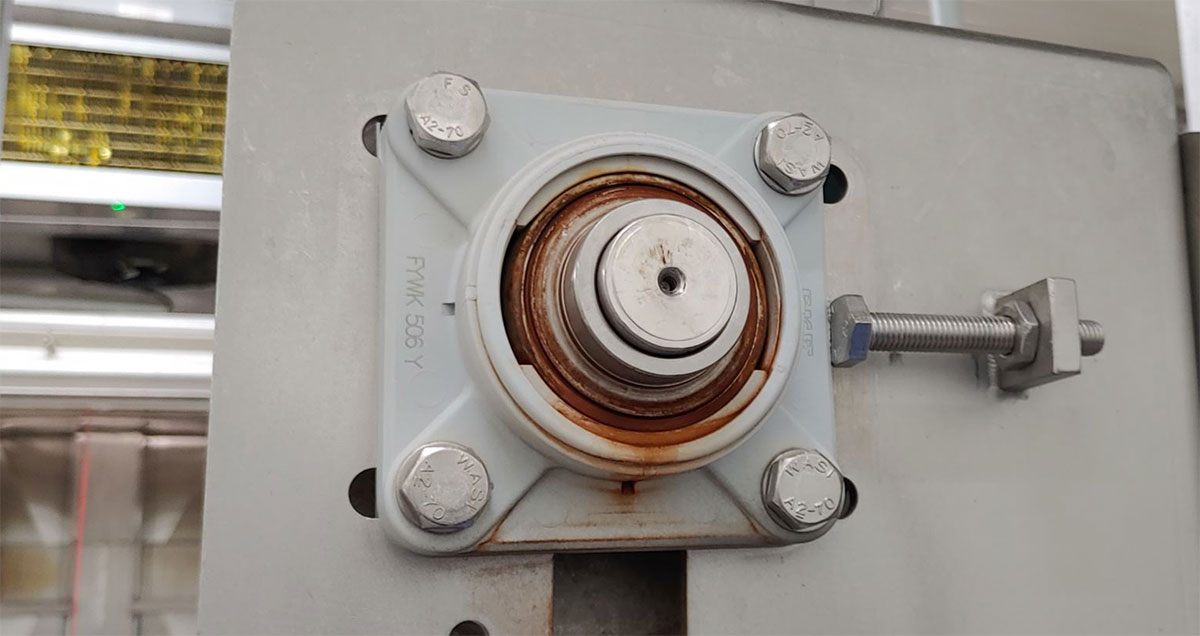

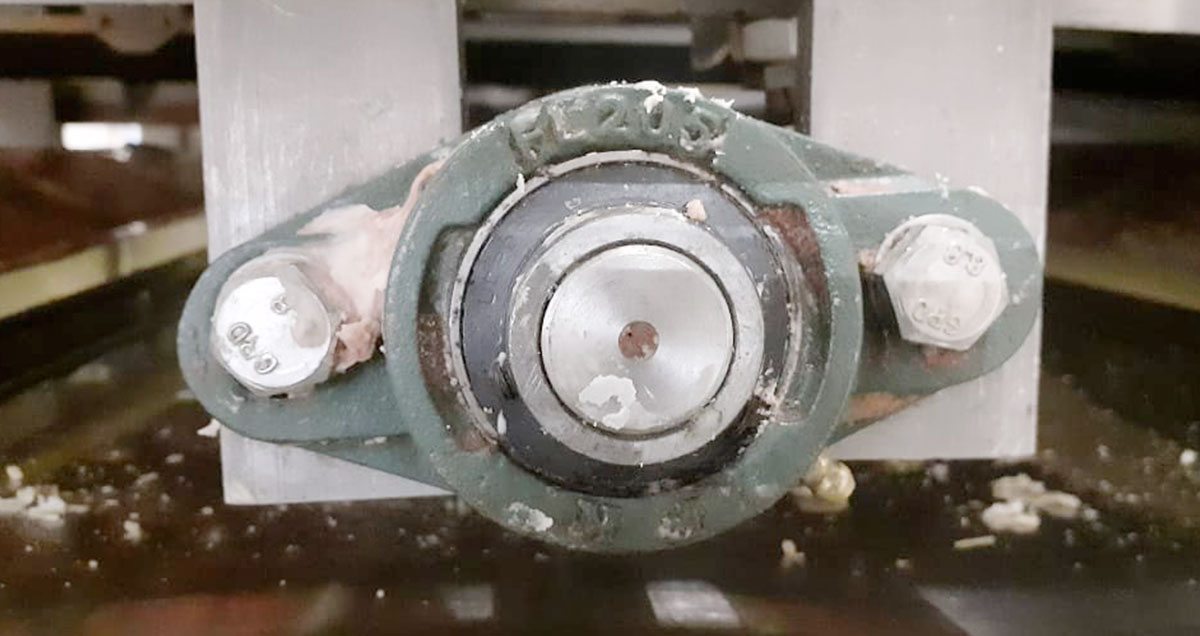

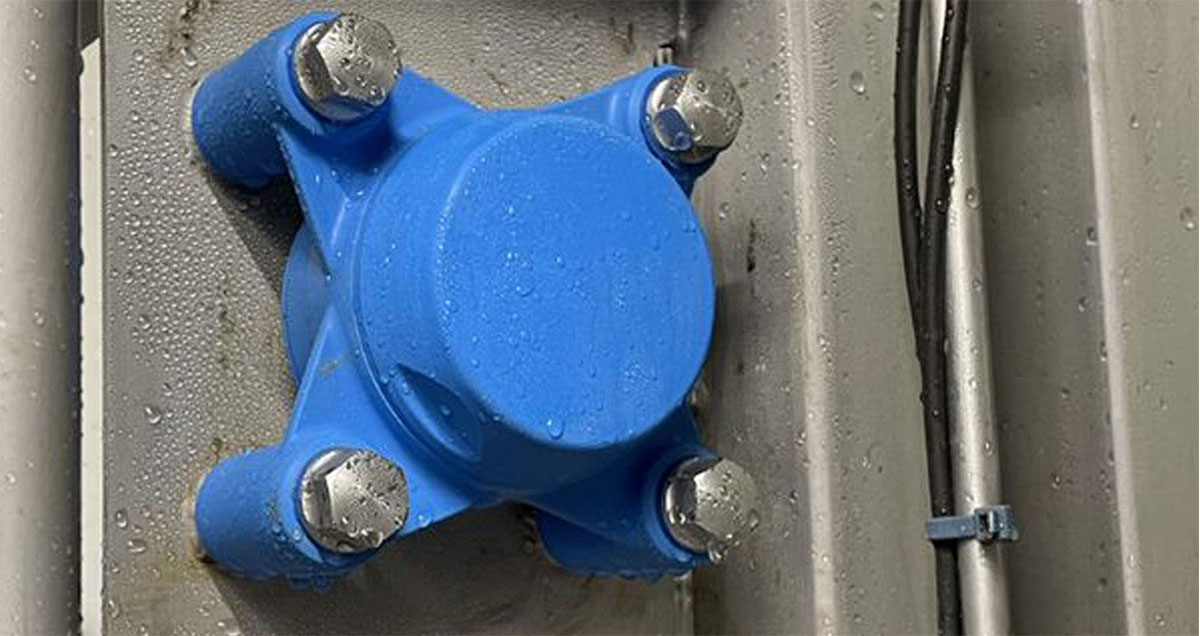

Our bearing houses are certified by EHEDG, 3-A and USDA standards. At the same time, our bearing houses are IP69K-classified. The product group consists of five different types of bearing houses fitted with ceramic or standard stainless steel bearings.

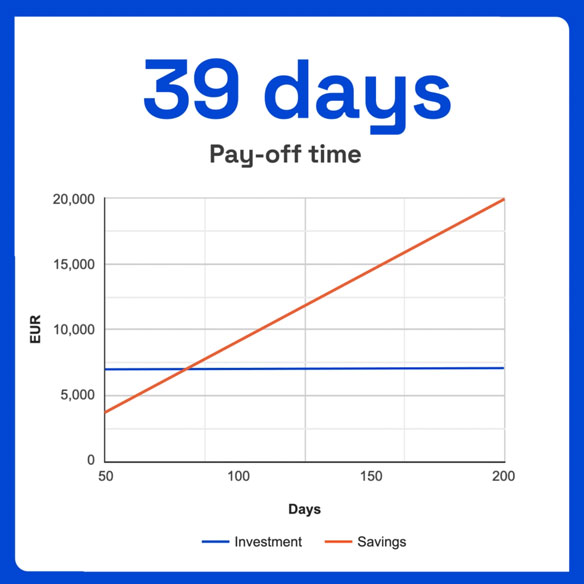

In choosing bearing houses from NGI optimized with ceramic spherical ball bearings, you will be able to reach optimal quality, robustness, and stability. The bearing houses are lubrication free which minimizes maintenance and the need for grease, thereby, minimizing the risk of contaminating the product.

To ensure an EHEDG, 3-A, and USDA solution, our bolts and nuts are required for mounting. Furthermore, the USDA certification also requires the use of spacers.