Tank Support Bolts and Weld Mounts - Overview of Groups and Features

We offer a range of tank support bolts and weld mounts designed to provide robust support and ensure hygienic standards across various production environments. Each product is tailored to minimize cleaning effort and enhance stability, making them ideal for demanding applications.

- Material and Sizes: Our tank support bolts are crafted from high-quality materials, with models featuring a fixed blue sealing ring detectable by scanning systems. The weld mounts, also known as adjustable ball feet or bullet feet, are available in various sizes and can be customized to accommodate different pipe dimensions.

- Construction Details: All tank support bolts and weld mounts are made from high-grade stainless steel either AISI 304 or AISI 316, providing exceptional corrosion resistance and longevity. The hygienic versions feature a sleeve to optimize for easy cleaning and reduce contamination risks. These components are designed to handle significant weight loads and floor inclines, ensuring stability and safety.

- Ease of Installation: Designed for straightforward installation and easy adjustment, our tank support bolts and weld mounts ensure a smooth setup process. The support bolts can handle inclines of up to 20°, and the weld mounts can be adjusted internally for optimal fit and stability.

Expand the following paragraph to discover a precise overview of each of our product categories along with direct access to them.

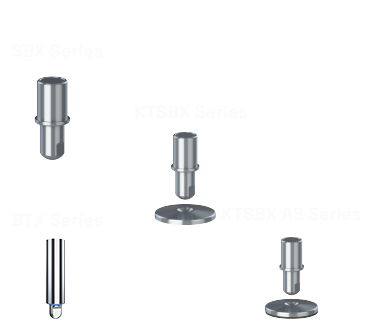

Product Variants:

Our tank support bolts are crafted to manage substantial weight loads and are well-suited for tanks, vessels, and heavy machinery.

- SBX Model: Supports loads up to 493,600 N without a footplate. It can handle inclines of up to 20° and fits inside the machine leg.

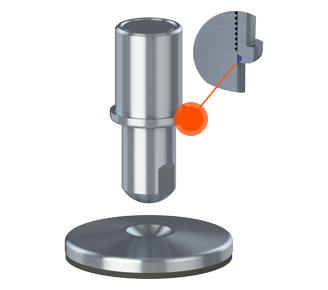

- KTSBX Model: Features a separated footplate, support bolt, and welding connector. The centrally located depression in the footplate secures the support bolt. This model supports a maximum weight of 200,000 N and can handle inclines of up to 20°.

- KTSBX AS Model: Similar to the KTSBX model but includes anti-vibration, anti-slip rubber underneath the footplate. Maximum weight of 30,000 N. This model can also handle inclines of up to 20°.

Choose our tank support bolts to secure your heavy machinery with a hygienic design. Our solutions provide unmatched reliability, safety, and cleanliness in demanding production environments.

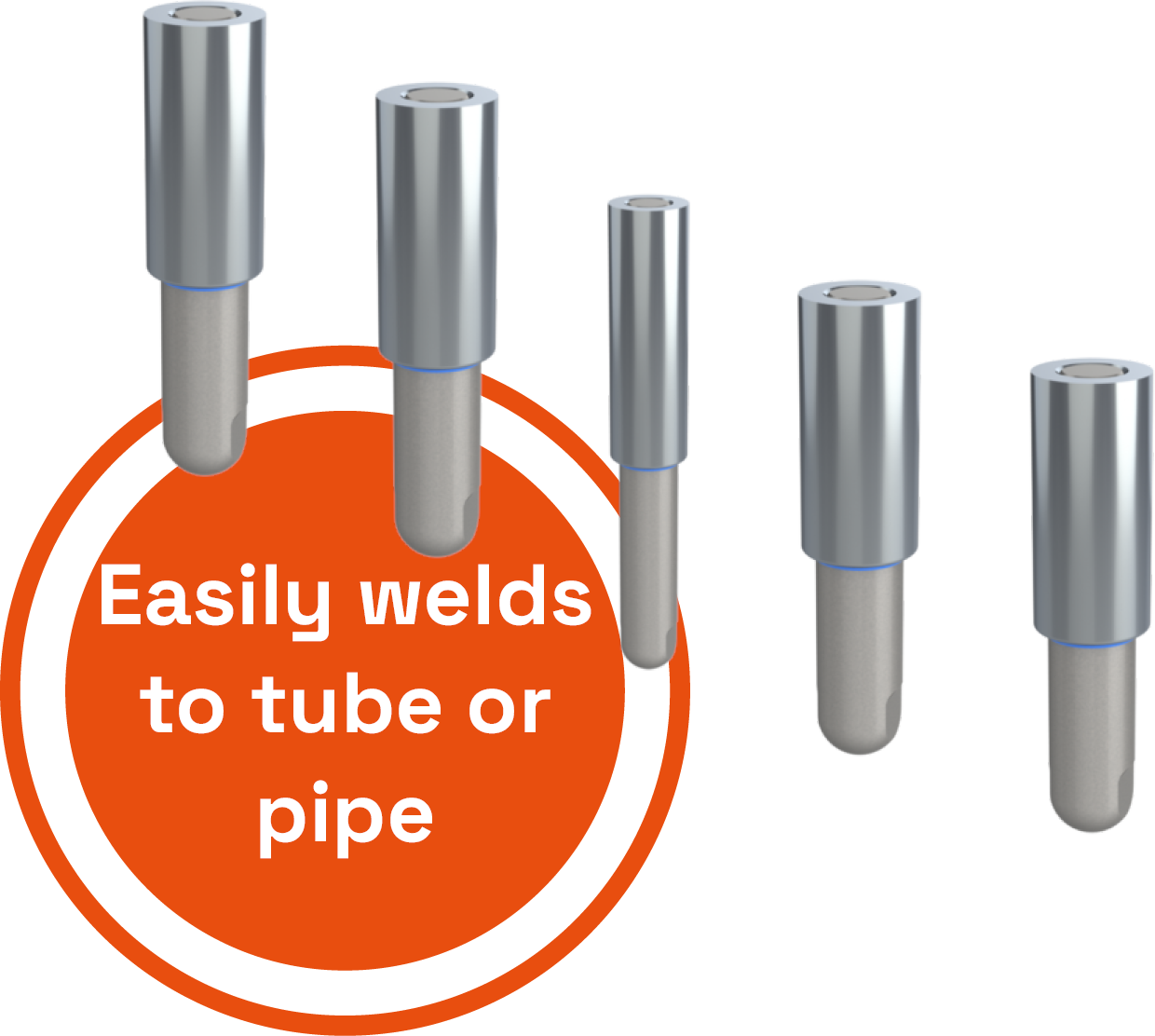

Our BTX weld mounts, also known as adjustable ball feet or bullet feet, are ideal for food processing machinery, offering improved hygiene, stability, and space utilization.

- BTX Model: Supports up to 112,000 N and is designed to weld externally at the bottom of the machine.

BTX Weld Mounts: Unlike levelling feet, weld mounts are adjusted internally within the spindle and do not need to be installed inside the equipment. They can be customized to accommodate pipes and are typically positioned at the extremities of pipes and tubes.

You can select the various product groups using the product group filter provided in the product finder above.

If you face any challenges in selecting a suitable tank support bolt or weld mount for your requirements, feel free to reach out to us for guidance.

If you have a unique project that requires specific measurements, we can provide custom solutions to meet your needs. With over 50 years of experience in supplying components, we are well-prepared to assist you!

Read moreRead less