Elevate hygiene standards, reduce maintenance expenses, enhance energy efficiency, and ensure accurate management of production procedures.

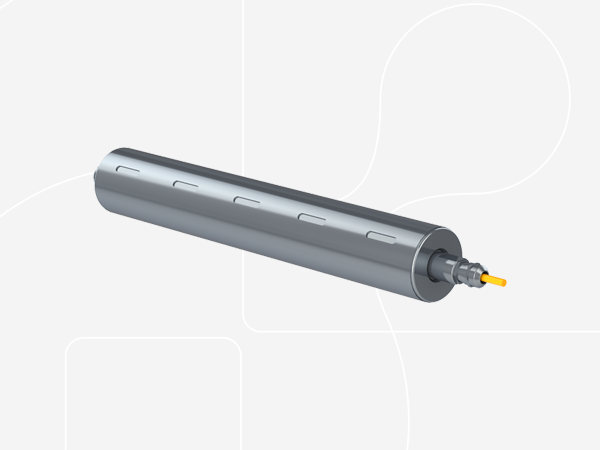

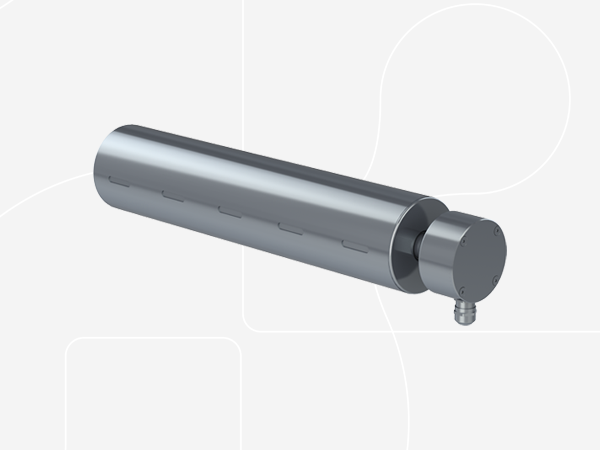

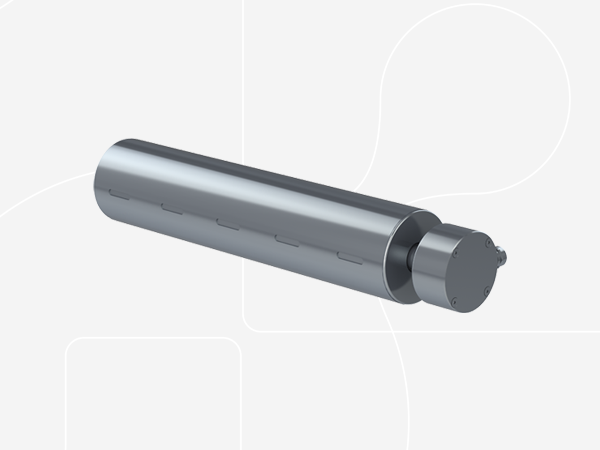

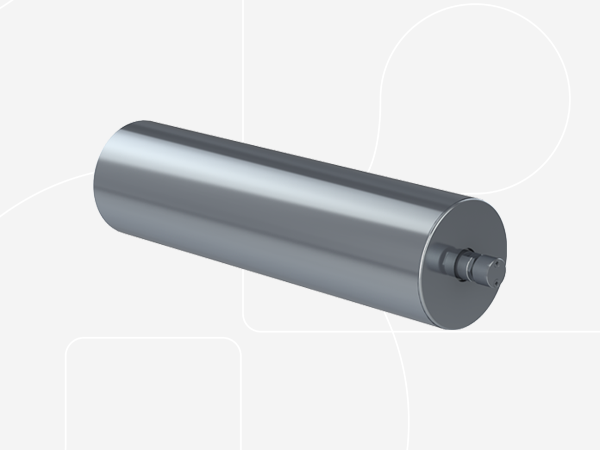

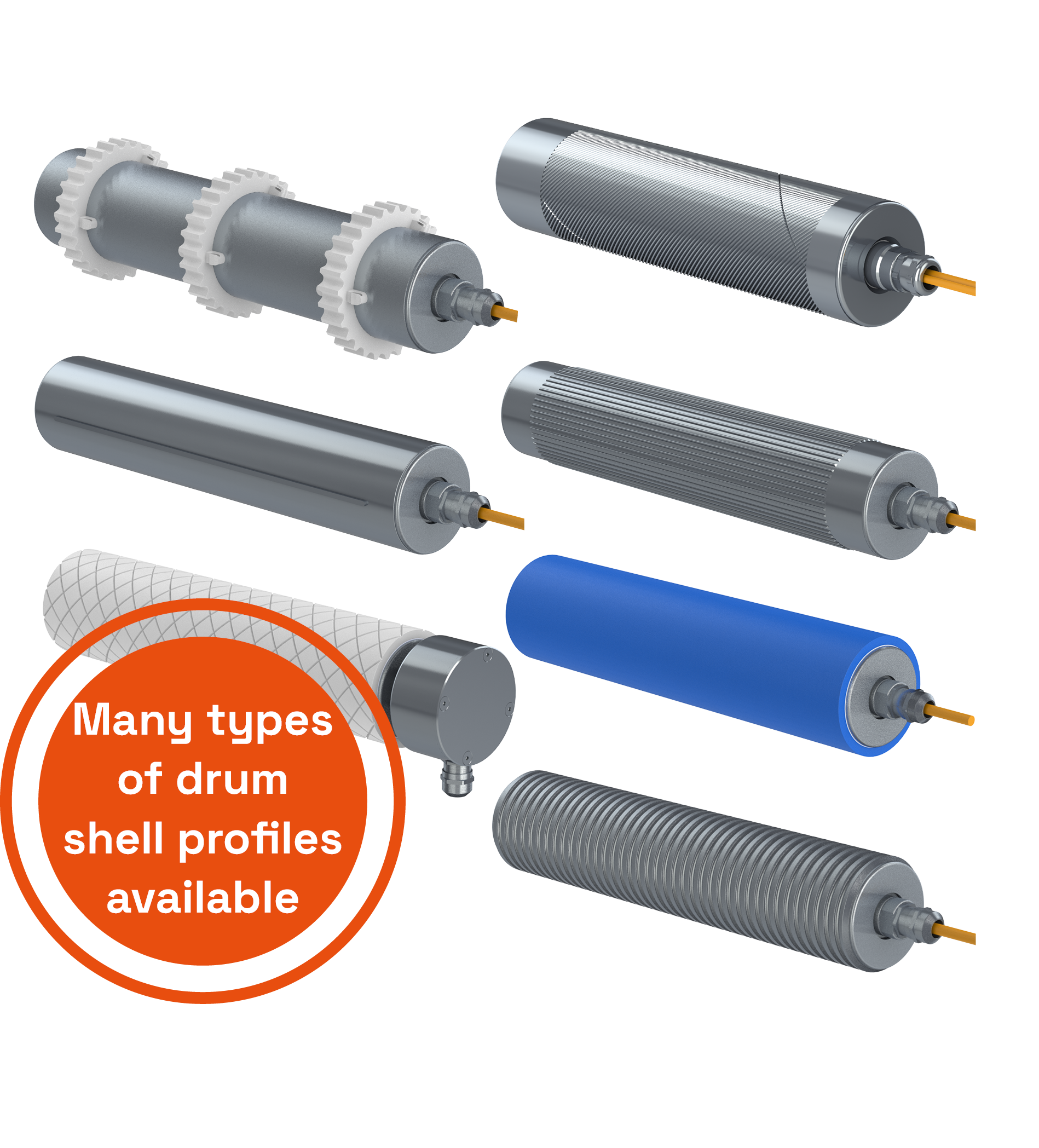

There are plenty of advantages to using our synchronous motors. For example, they enable superior control over speed and torque, which is essential for precise tasks like mixing, conveying, and sorting in food processing applications.

Furthermore, our synchronous motors boast higher energy efficiency than asynchronous motors, resulting in long-term cost savings through reduced energy consumption.

Another advantage of our synchronous oil-free drum motors is a longer lifespan. They require less maintenance than asynchronous motors, eliminating the need for oil changes and minimizing downtime risks. Asynchronous motors necessitate lubrication, potentially introducing contaminants into food production.

Synchronous oil-free drum motors typically feature a more compact design than asynchronous motors, facilitating easier integration into existing food processing equipment and conveyor systems.

Finally, by using our oil-free synchronous drum motors you help reduce the environmental impact associated with traditional lubrication methods, eliminating the possibility of oil leaks or spills and fostering a cleaner, safer work environment.

Therefore, there are numerous benefits, and we can provide additional assistance regarding the cost and advantages of transitioning to our synchronous drum motors. Feel free to reach out to us for further information!