Are You Struggling to Keep Your Equipment Sanitary?

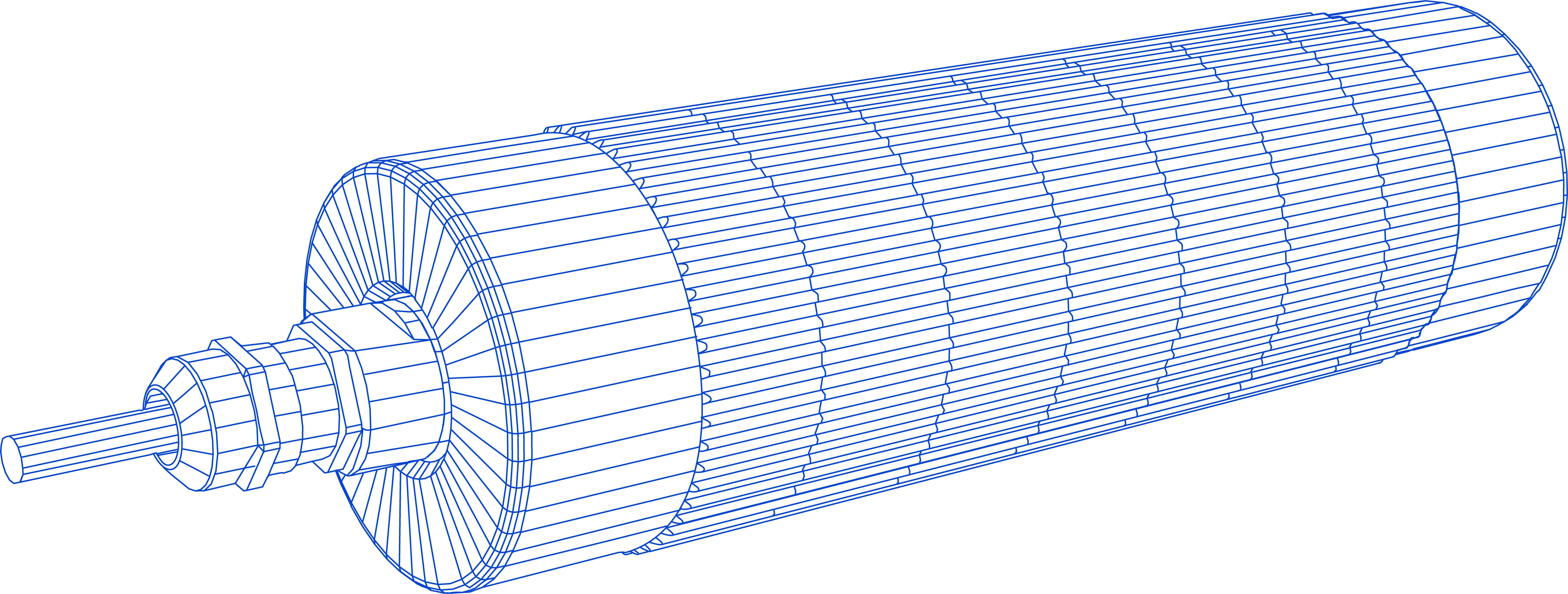

In the food industry, hygiene isn’t just important—it’s non-negotiable. Drum motors have a sealed, enclosed design that keeps contaminants out, making them easy to clean and sanitize. With no exposed moving parts or crevices where dirt can hide, they meet the strict hygiene standards demanded by food processing facilities.

Gear motors, on the other hand, have external components like gears and chains that are harder to clean and more prone to trapping bacteria.

Are you energy-conscious?

Drum motors are designed to be highly efficient, often achieving better energy performance than gear motors. With fewer components and an integrated design, they reduce energy losses, helping you save on operational costs.

Gear motors, while effective, typically have more mechanical losses due to their complex setup. Over time, these inefficiencies can add up, making drum motors a more cost-effective choice for energy-conscious businesses.

Is Limited Space Slowing Down Your Production?

Space is often at a premium in food production facilities. Drum motors are compact and integrate directly into the conveyor, freeing up valuable floor space. Our new Compact motor takes this advantage even further, delivering powerful performance in an even smaller footprint.

Gear motors, by contrast, require more room due to their external components and additional mounting hardware.

Tired of Frequent Repairs and Downtime?

Drum motors are built to last with minimal maintenance. Their enclosed design protects internal components from wear and tear caused by environmental factors like dust, water, and food particles. This translates to longer lifespans and fewer maintenance interruptions.

Gear motors require regular upkeep, including lubrication and part replacements, which can increase downtime and maintenance costs.