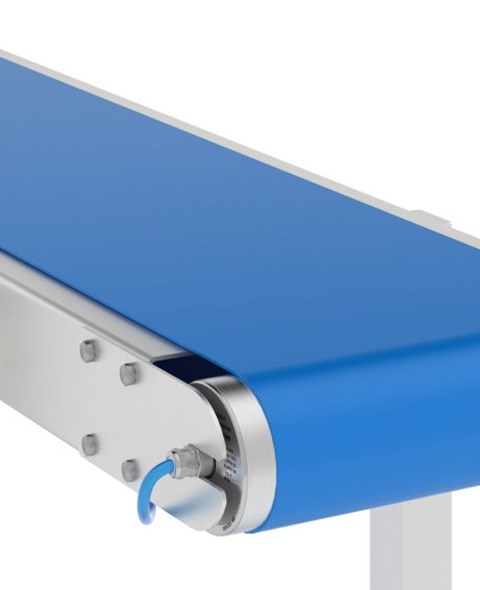

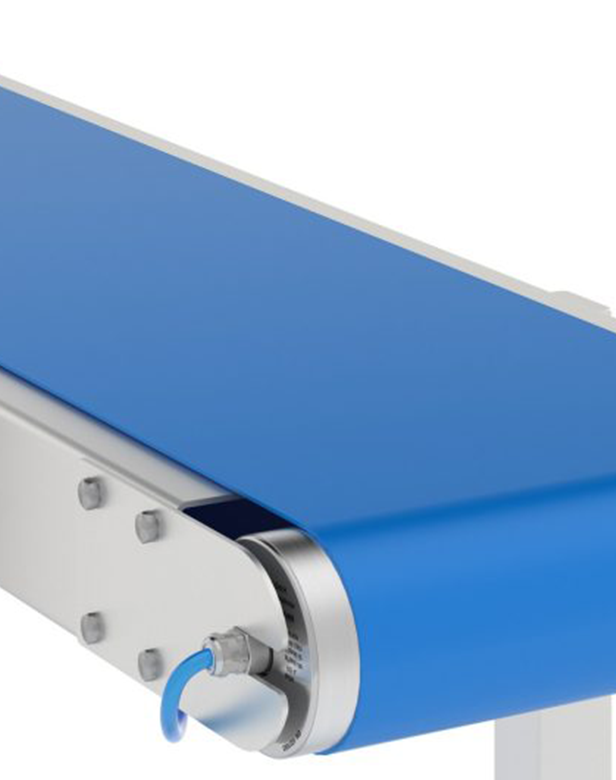

Drum Motor Basics: Less is more!

Drum motors have become the standard for many materials handling tasks. Their advantage over alternative drives lies in the fact that the motor-gear unit sits inside the belt or conveyor deflection roller, saving a great deal of space, components, and design effort.