Designed for Hygiene from the Ground Up

All NGI synchronous motors are IP69K rated, meaning they can withstand high-pressure, high-temperature washdowns. But the design goes beyond IP ratings.

The motor surfaces are smooth and self-draining. There are no exposed bolts or crevices where bacteria can collect. All materials are compatible with FDA-approved cleaning agents and designed in line with EHEDG guidelines for hygienic processing equipment.

This makes them ideal for meat, dairy, bakery, and other food environments where hygiene is critical, and every washdown needs to be fast and effective.

Easy Installation and Retrofit Options

Our motors are designed to fit into the same footprint as many standard asynchronous drum motors. This makes retrofitting simple. The external dimensions, shaft geometries, and cable routing options are all designed to support quick replacement.

We provide full technical drawings and wiring diagrams to ensure compatibility. In most cases, you won’t need to modify your conveyor design to upgrade to synchronous motors.

Compatible with Standard VFDs

Synchronous motors require a variable frequency drive (VFD) for speed control. Our motors support both open-loop and closed-loop vector control, depending on your application needs.

Most industrial VFDs on the market are compatible, and we offer guidance to help you select and configure the right one. Once installed, the system provides smooth speed transitions, stable torque output, and precise control over acceleration and deceleration.

Pricing and ROI – An Investment That Pays for Itself

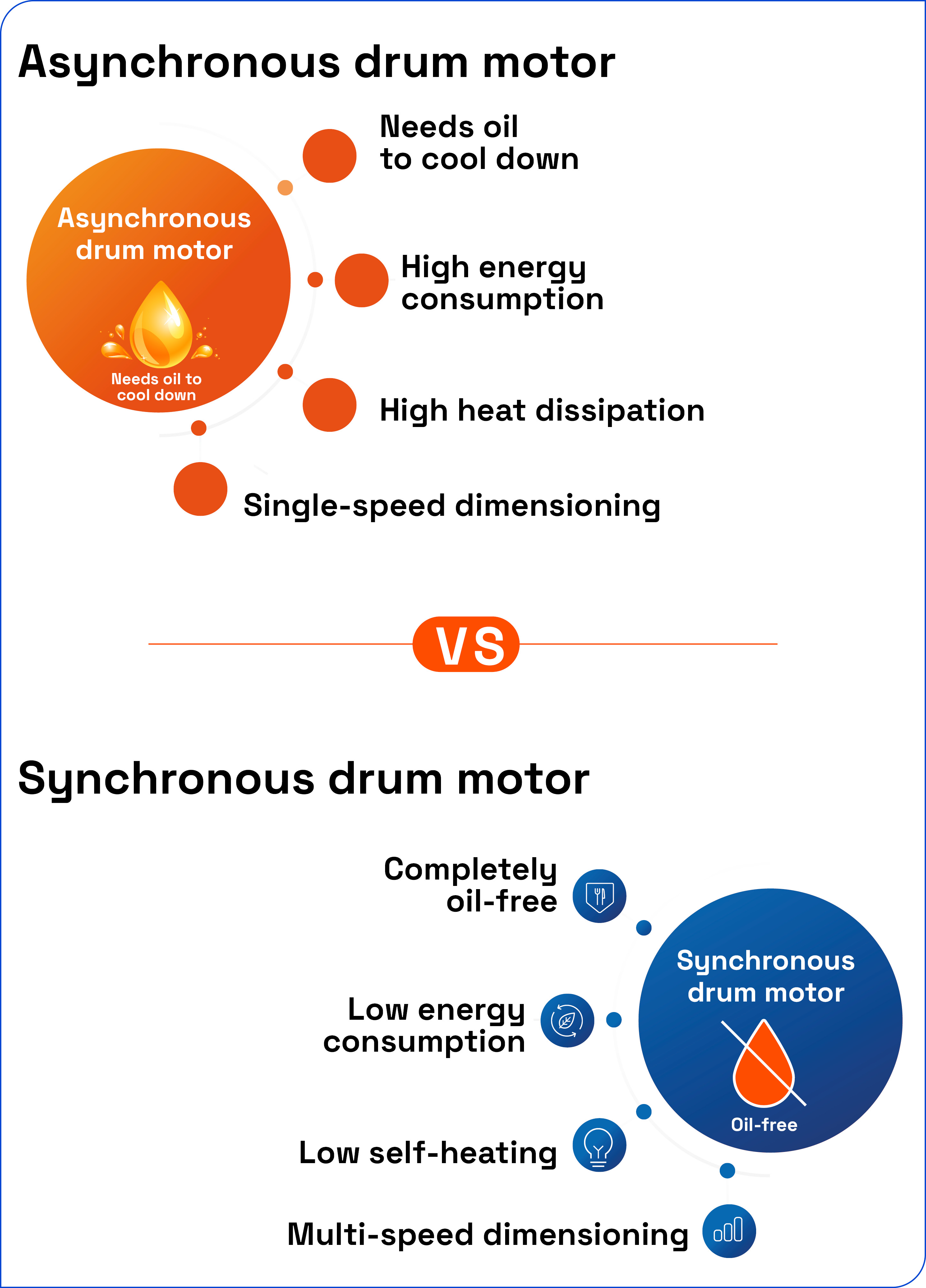

We often hear the question: "Aren’t synchronous motors more expensive?" The answer is yes, at the point of purchase. But that’s only part of the story.

When you calculate total cost of ownership, the numbers speak for themselves. Thanks to energy savings, no oil-related maintenance, longer service life, and fewer unplanned stoppages, most customers see a return on investment within 12 months.

To make this easier to evaluate, NGI provides an ROI calculator specifically for drum motors. It allows you to input your current energy costs, motor usage, and maintenance figures to see how quickly the upgrade will pay off.