How to Prevent Fretting in Bearing Houses

- and Why It Matters More Than You Think

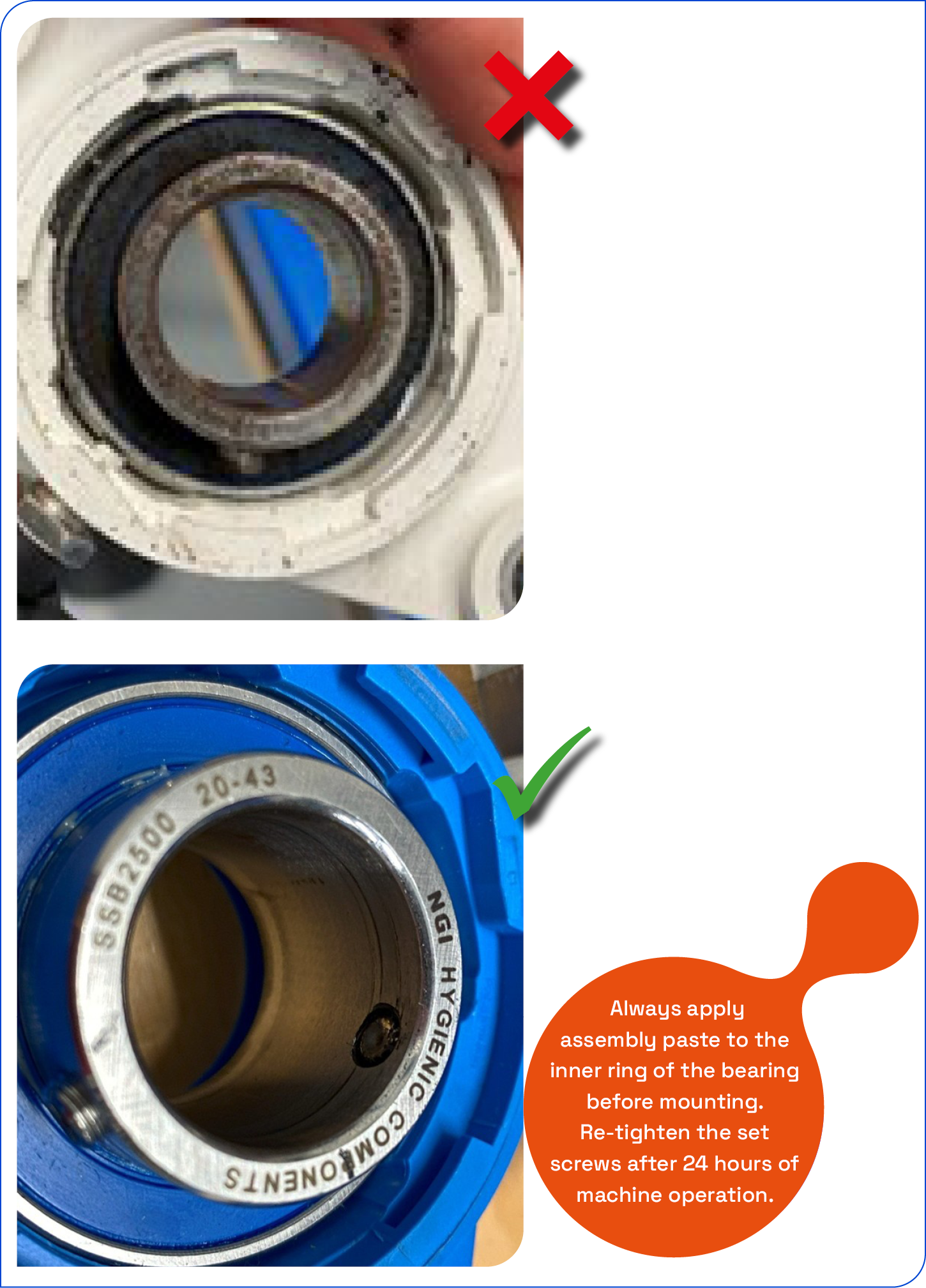

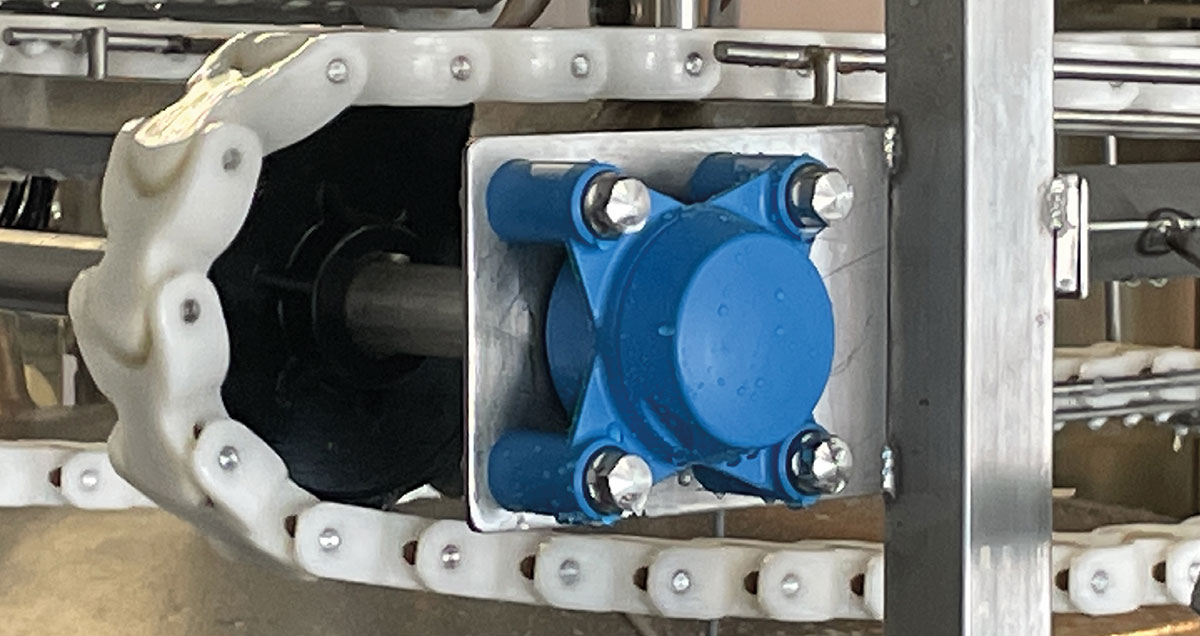

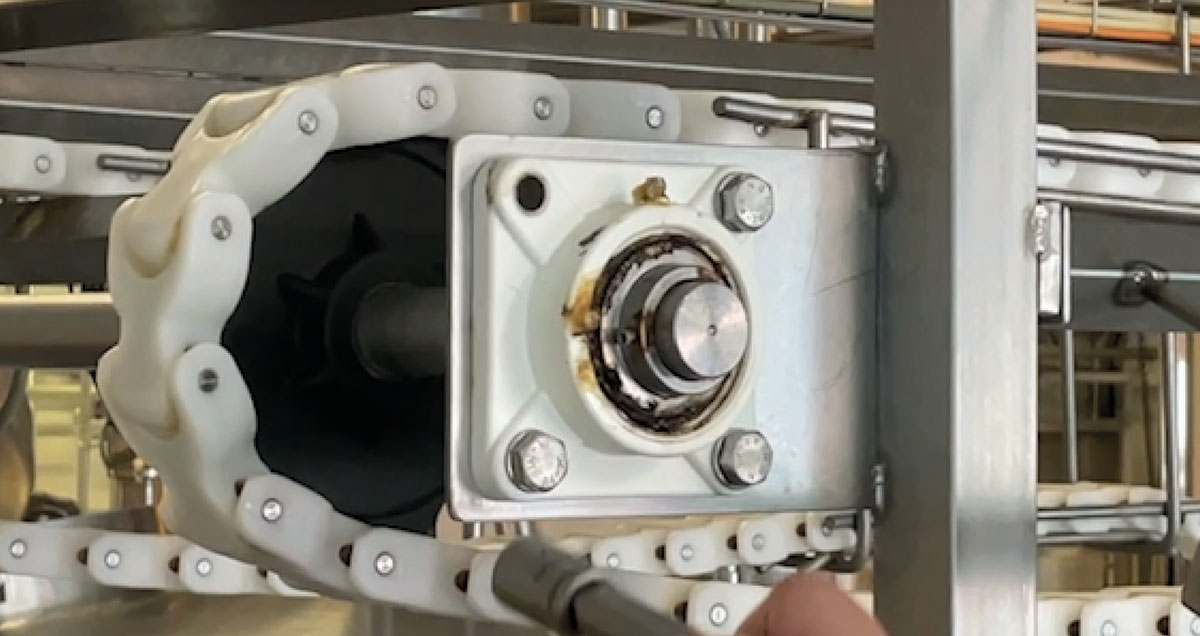

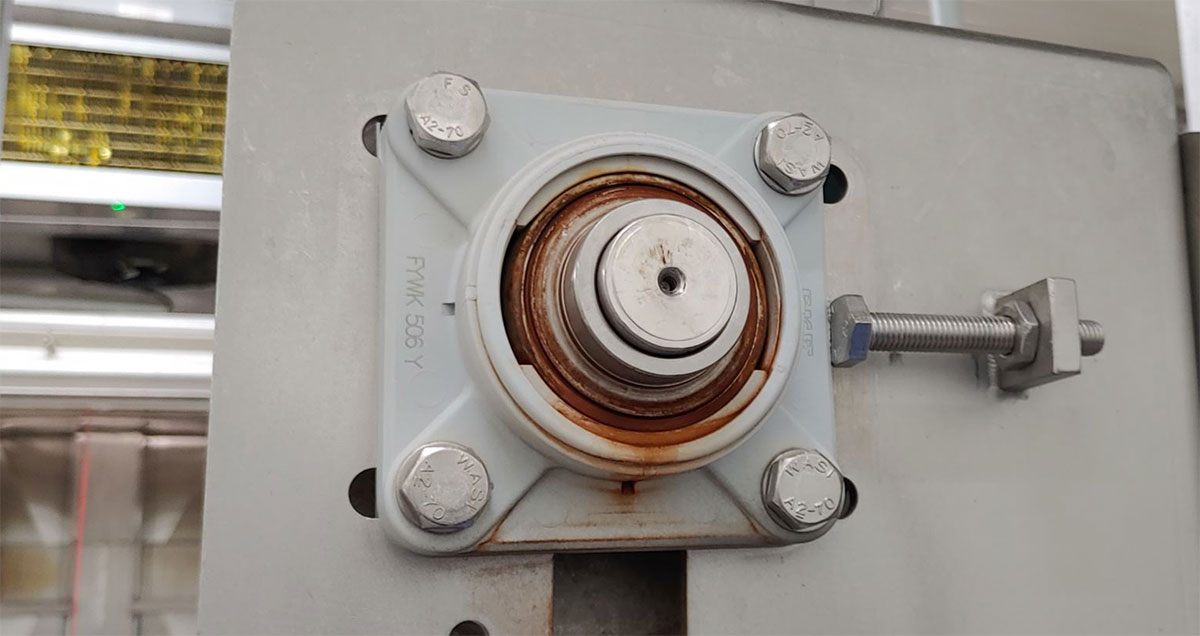

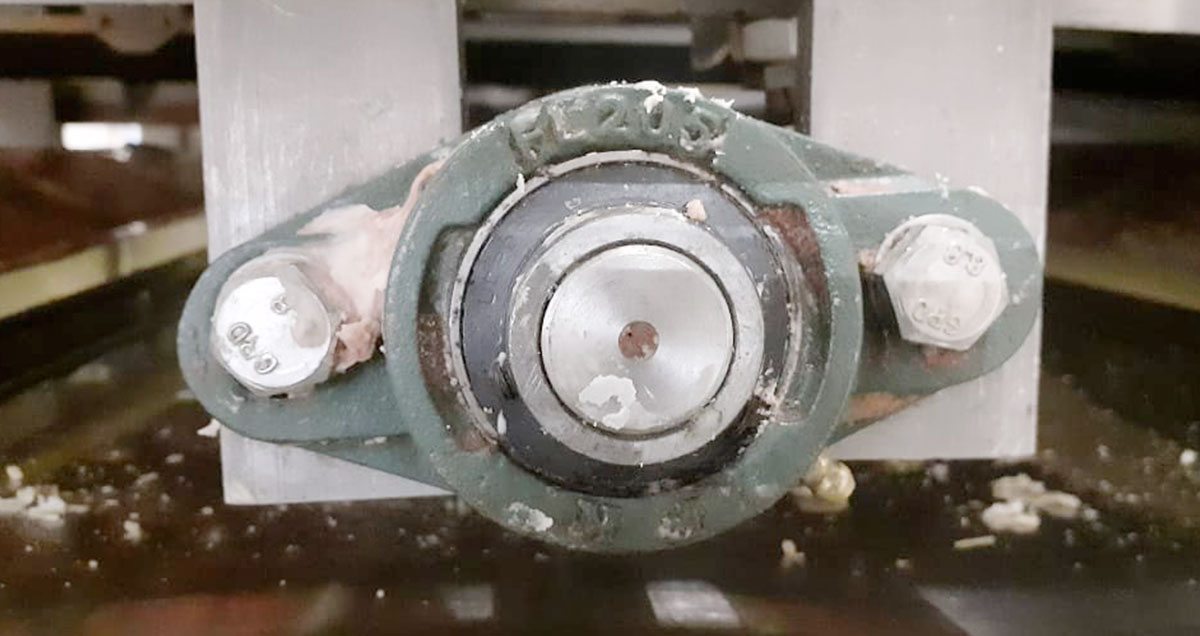

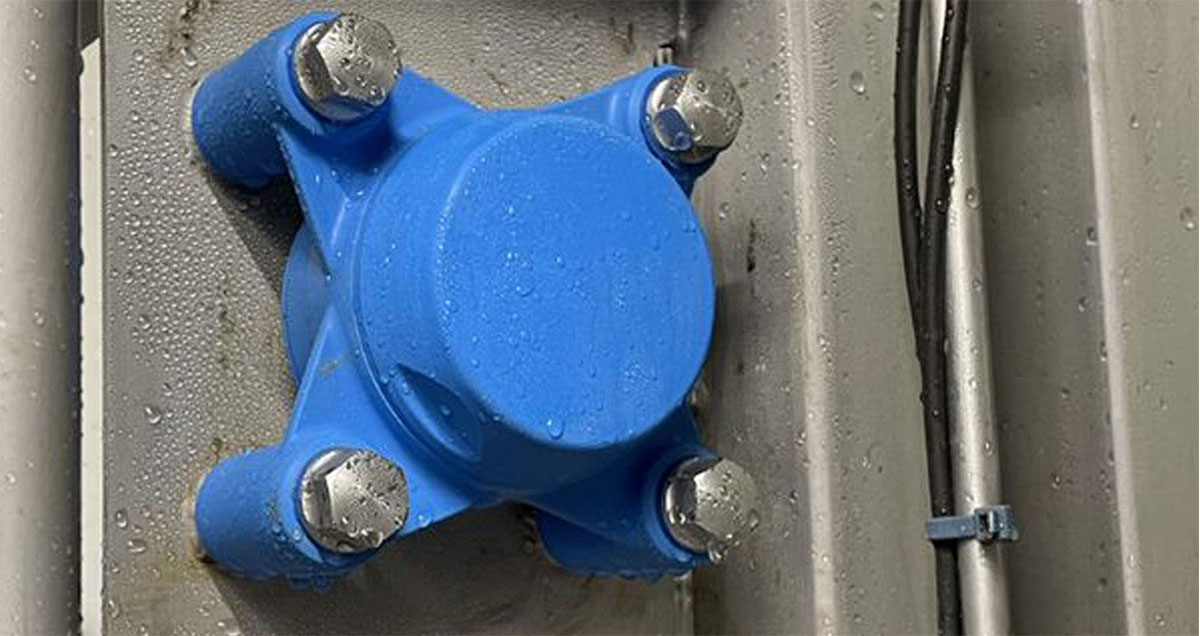

In the food industry, every component must contribute to hygiene, efficiency, and long-term reliability. Fretting corrosion is one of the most common and costly causes of premature bearing failure, especially in stainless steel bearing units used in hygienic environments. Despite this, it's often overlooked or misunderstood. Many of the failures we see in the field trace back to a simple, preventable issue: improper installation.

At NGI, we design bearings that are lubrication-free in daily operation. But that doesn’t mean they are maintenance-free during installation. Grease is essential, not as a long-term lubricant, but as a physical barrier that prevents micro-movement between the shaft and the bearing’s inner ring. When skipped, fretting can occur within days.

In this article, we’ll explain what fretting is, why it occurs, and how proper installation can nearly eliminate it.

Written by Austin Davis, Category Manager, NGI