Hygienic Product Line: Certified Bolts

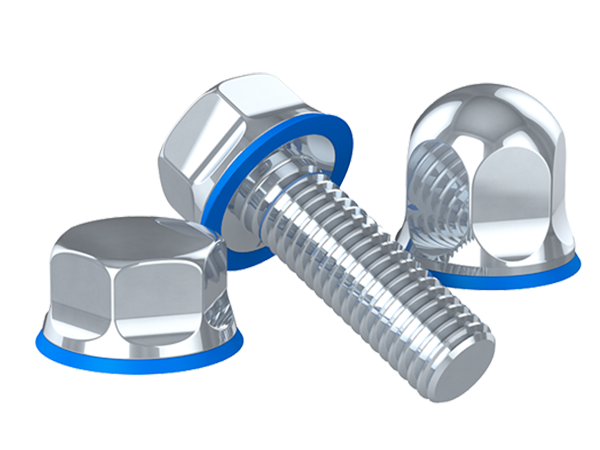

NGI provides certified hygienic BXH bolts that come with blue sealings. These sealings effectively block water and bacteria, ensuring a hygienic environment.

Additionally, the bolts feature self-draining surfaces with a maximum roughness of 0.8 μm Ra. Despite their enhanced design, the bolts maintain the same sizes as standard bolts, including wrench sizes and thread heights. This makes it incredibly convenient to upgrade and replace standard bolts with NGI's hygienic BXH bolts.

These bolts are suitable for use in any machinery within hygienic wash-down environments that are certified.