See the risk. Solve the risk.

Updating equipment with hygienic design isn’t just about compliance; it’s about staying competitive and giving your customers confidence.

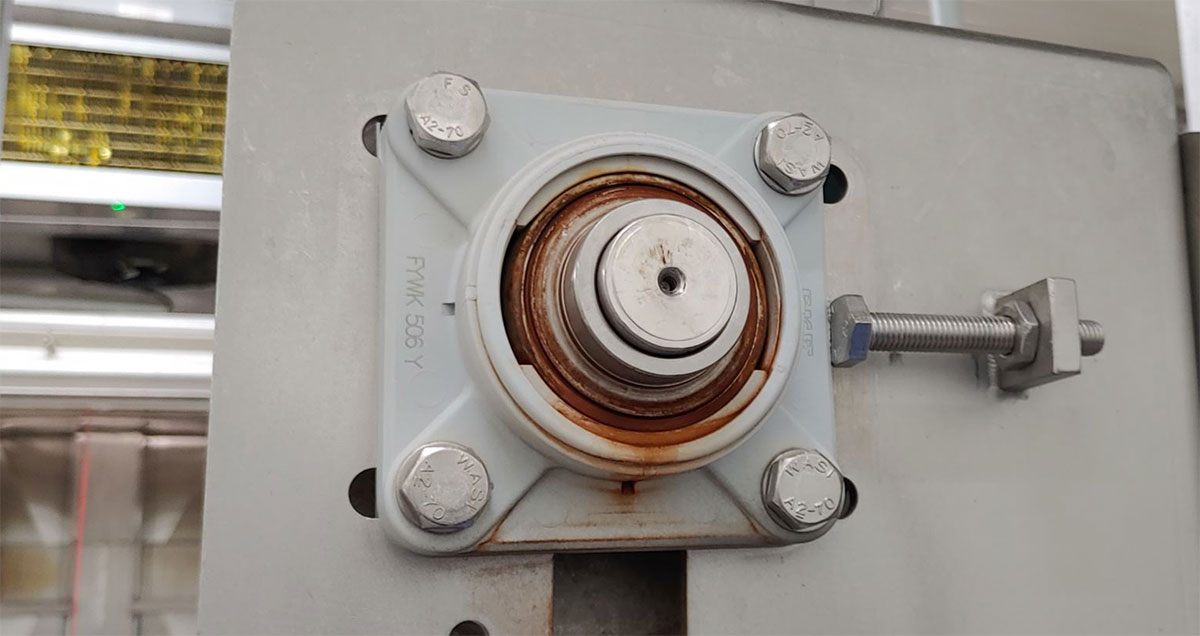

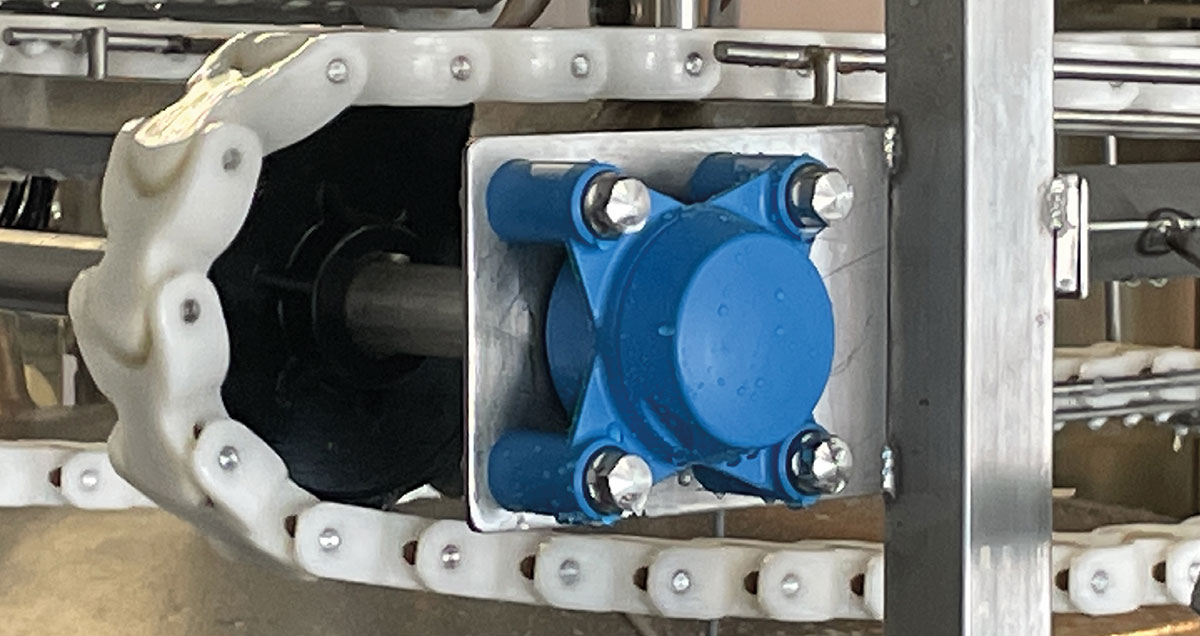

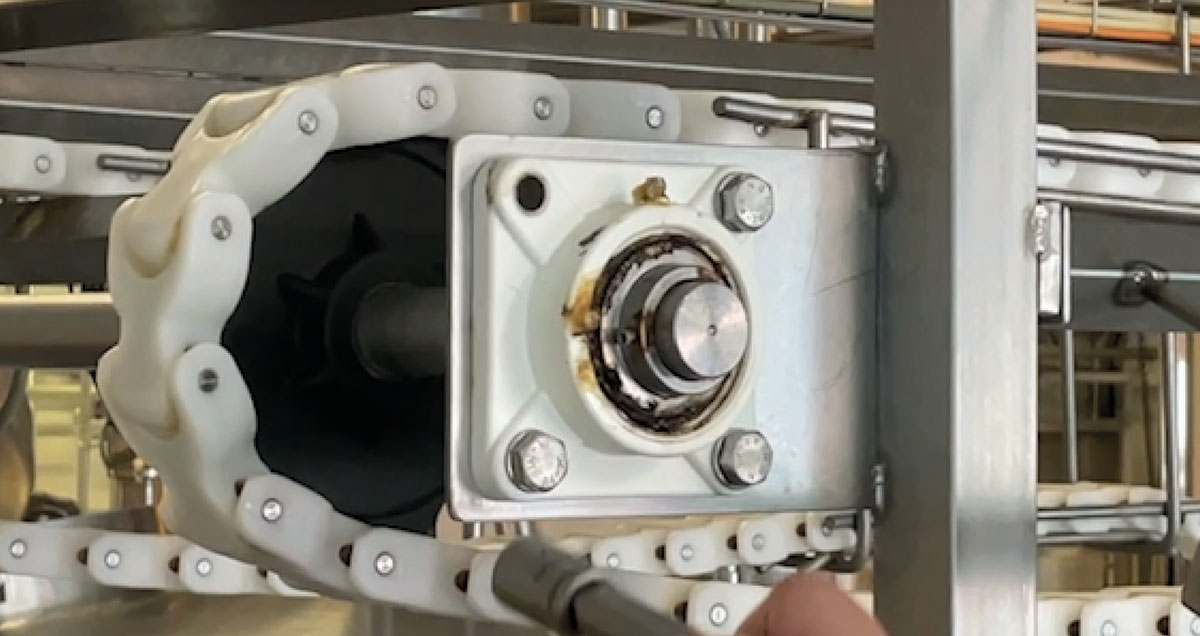

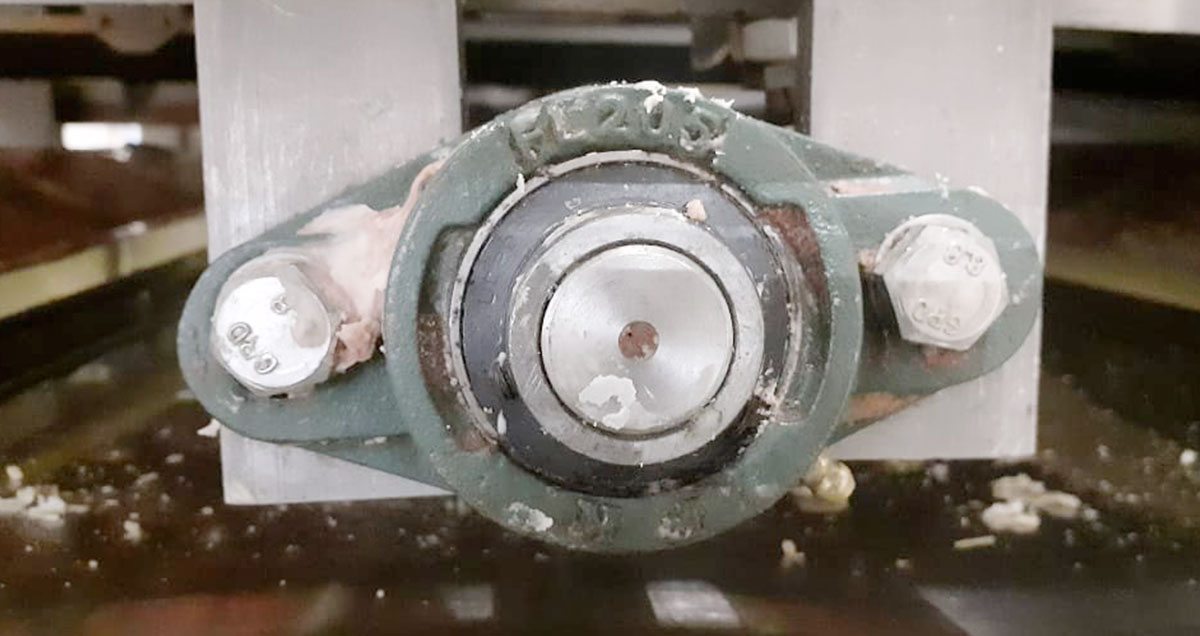

Hidden hygiene issues in food processing equipment will lead to cross-contamination and costly downtime.

Let us help you help your customers