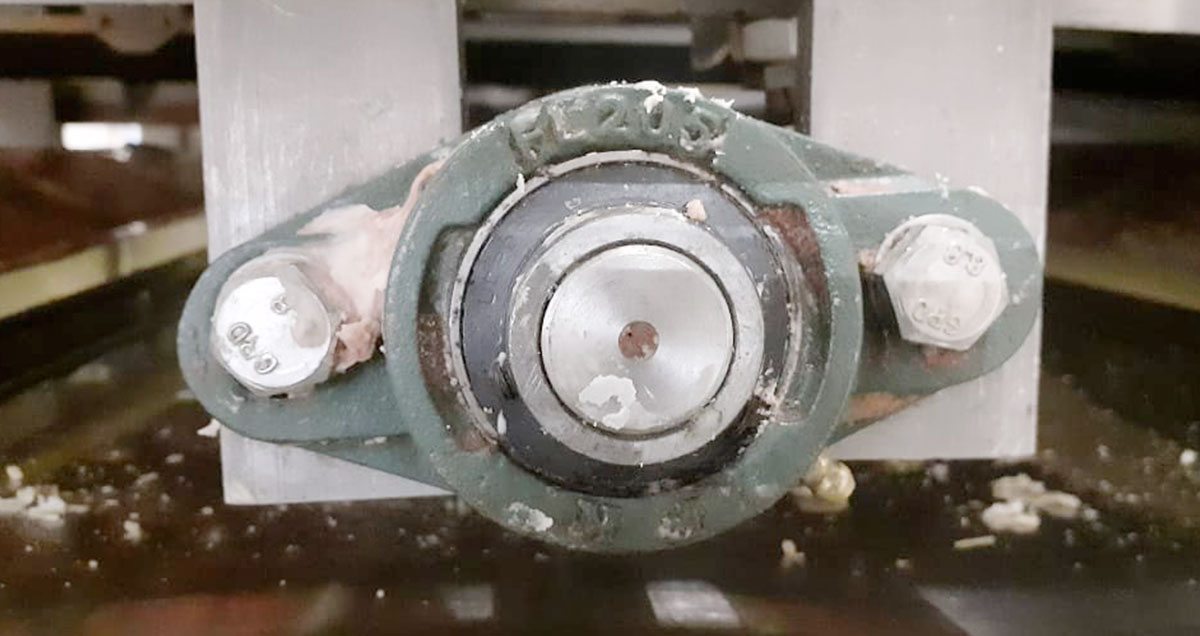

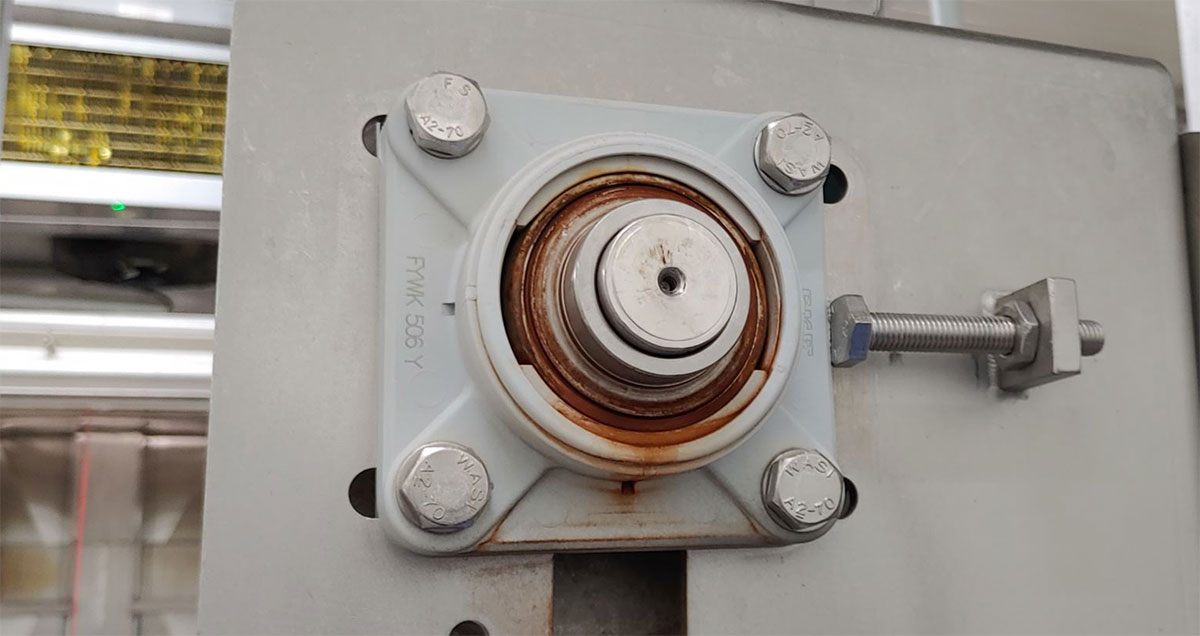

Choose the right components and minimize maintenance

Our bearing houses are unique as they have a patented, self-lubricated sealing system

Are you interested in minimizing downtime and increasing overall efficiency at your production facility?

Our products are meticulously designed to keep your machinery running and minimize time spent on maintenance.

Our bearing houses are unique as they have a patented, self-lubricated sealing system - no grease is needed. The sealing is designed to move with the shaft and is able to handle friction, heat, and wear thus extending the lifetime.

Furthermore, the bearing houses are designed to allow easy access for cleaning minimizing cleaning time, water usage, and the use of cleaning detergents.

If you fit your bearing houses with ceramic bearings it enables you to extend the lifetime by 4-8 times, reducing downtime and energy loss. You save as much as 60% on bearing-related costs.