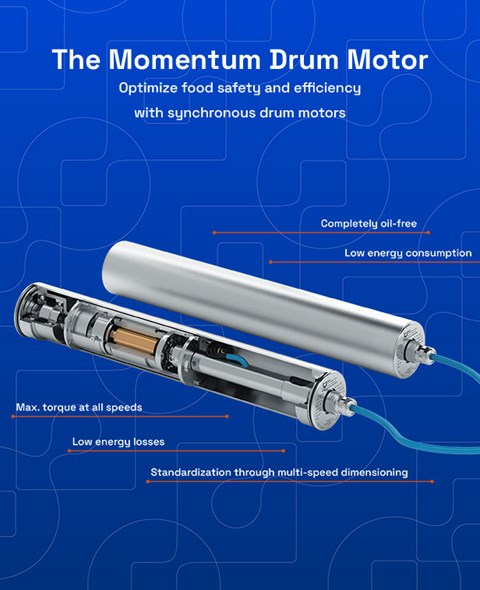

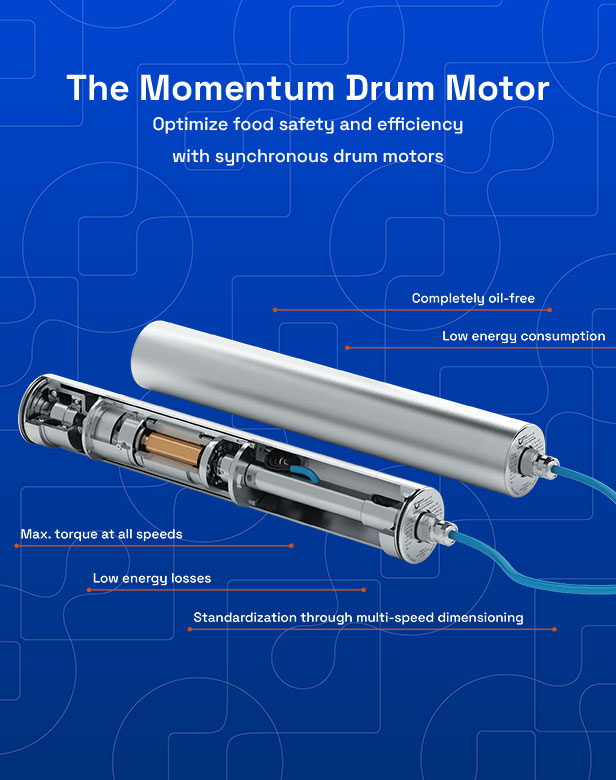

Drum motors in HACCP-compliant food processing

Stainless steel drum motors are highly valued in HACCP-compliant food processing. The fully enclosed construction of these drives enables high quality hygienic designs. All components such as motor and gear disappear inside the roller at the conveyor head, which is required for the deflection of the TPE or plastic modular belt. However, if oil is used inside the drum motors for cooling, care needs to be taken as leaking oil can become a source of contamination..