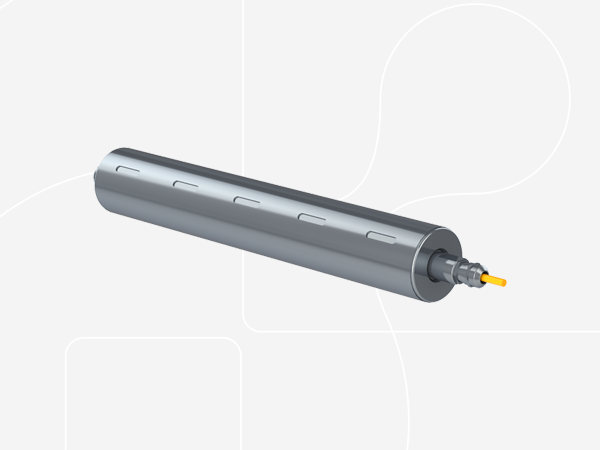

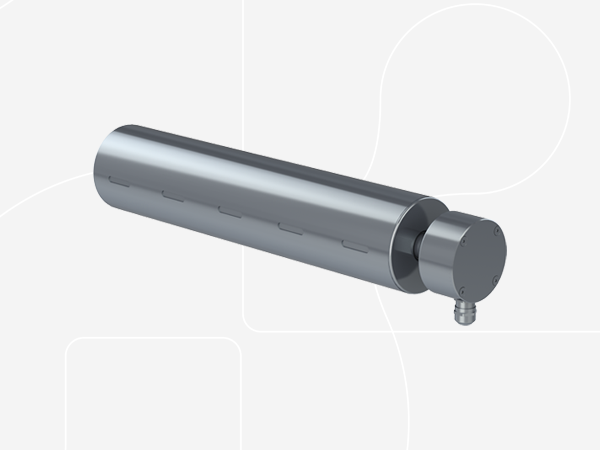

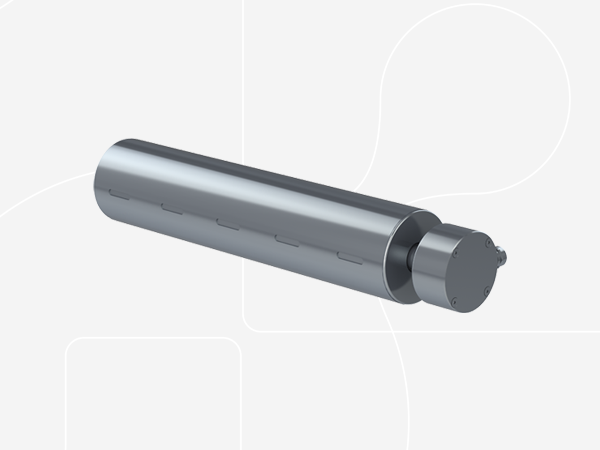

The use of our synchronous oil-free drum motors can help food processing companies improve hygiene standards, reduce maintenance costs, enhance energy efficiency, and ensure precise control over production processes

- Precision and Control: Our synchronous motors offer better control over speed and torque, which is crucial in food processing applications where precise control is required for tasks such as mixing, conveying, or sorting.

- Energy Efficiency: Our synchronous motors have a higher energy efficiency compared to asynchronous motors. This means cost savings for the food processing company by reducing energy consumption over time.

- Reduced Maintenance: Our synchronous oil-free drum motors typically have a longer lifespan and require less maintenance compared to asynchronous motors. They eliminate the need for oil changes and reduce the risk of downtime due to maintenance activities.

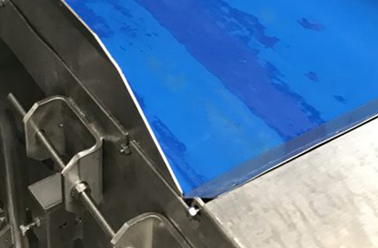

- Higher food safety: Asynchronous motors often require lubrication, which can introduce contaminants into the food production process.

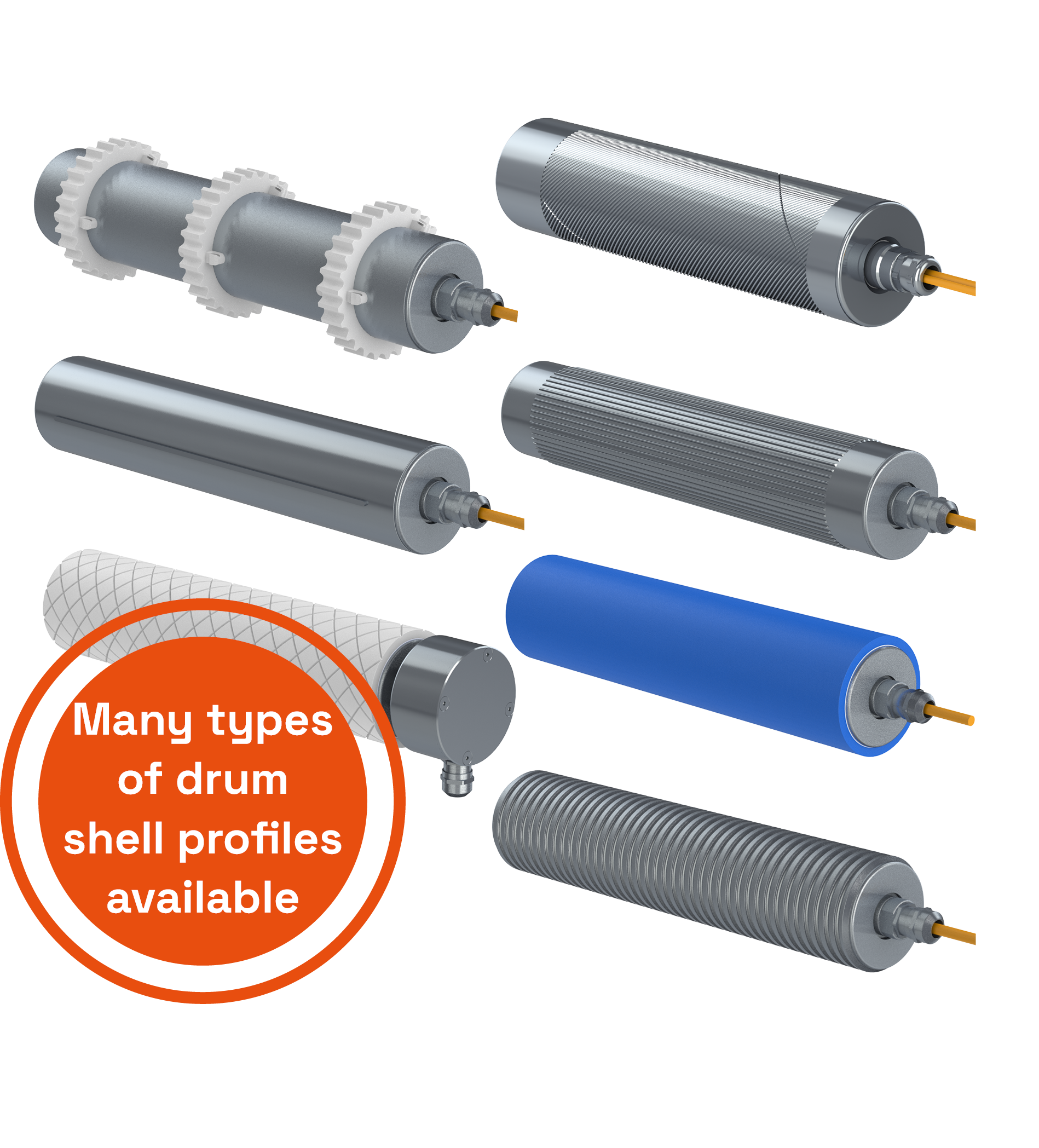

- Compact Design: Synchronous oil-free drum motors often have a more compact design compared to asynchronous motors, making them easier to integrate into existing food processing equipment and conveyor systems.

- Environmental Friendliness: The use of oil-free synchronous drum motors reduces the environmental impact associated with traditional lubrication methods. It eliminates the risk of oil leaks or spills, promoting a cleaner and safer working environment.