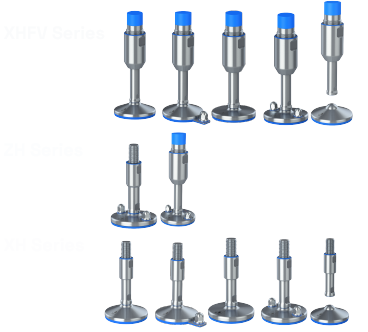

Certified Hygienic levelling feet - a summary of groups and features

Our top-quality hygienic industrial machine levelling feet are certified and designed to meet the strictest standards of cleanliness and durability. They are ideal for industries such as food processing where hygiene is of utmost importance.

Constructed from stainless steel, these levelling feet are corrosion-resistant, effortless to clean and built to withstand rigorous cleaning agents.

Furthermore, you can look forward to a 32% decrease in cleaning expenses with NGI hygienic adjustable feet compared to fully threaded levelling feet, as cleaning becomes less resource-intensive (time, water, detergents etc.).

Our hygienic machine feet and their sturdy construction guarantee long-lasting performance and reliability, making them a cost-efficient option for ensuring optimal equipment functionality.

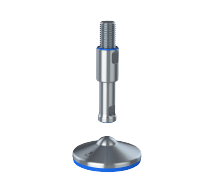

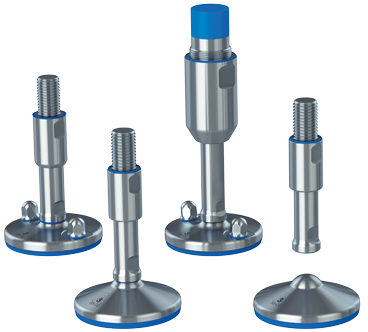

- Material and Sizes: Our hygienic levelling feet are available in foot diameter sizes ranging from 65mm to 150mm. All feet can be made in AISI 304 or AISI 316 stainless-steel and are equipped with vulcanized FDA-approved rubber to prevent slippage and reduce vibration transmission.

Rubbers are available in black, blue and white NBR and black EPDM.

- Construction Details: All feet are made from high-quality stainless steel, utilizing a formed stainless-steel plate with vulcanized rubber on the underside, providing corrosion resistance and longevity. These feet have excellent vibration-damping properties

- Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a straightforward installation process.

Expand the following paragraph to discover a precise overview of each of our product categories along with direct access to them.

Product Variants:

These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression and tensile loads of up to 110.000N and 20.000N, respectively. These feet are both EHEDG and 3A certified and feature 2 mounting holes.

These machine feet are 3-A certified hygienic versions of our standard fully threaded levelling feet. They are available in sizes from 65mm to 150mm.

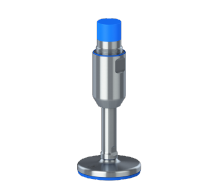

- XH variant: The XH system allows for exceptionally easy adjustment during installation, with a weight capacity of up to 70,000N and built-in slope compensation of up to 10°.

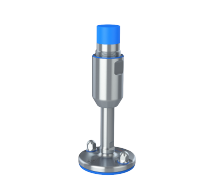

- XH-FIX variant: Includes floor fixing options and allowing up to 4,000N tensile load. Available in foot diameters 65, 80, 105 and 125mm.

- XHG variant: These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression loads of up to 110.000N and can compensate for floor slopes of up to 9°.

- XHJ variant: These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression and tensile loads of up to 110.000N and 20.000N, respectively.

The feet can compensate for floor slopes of up to 9°.

- XHT variant: Comes with a separate spindle and footplate, ideal for indexing machines that need to be moved and placed back precisely. The rubber underside provides a suction cup effect, preventing movement. This variant can handle an additional 5°, resulting in up to 15° slope compensation.

These feet enable lower minimum adjustment with high total adjustment and are 3-A certified.

- XHFV variant: The XH system allows for exceptionally easy adjustment during installation, with a weight capacity of up to 70,000N and built-in slope compensation of up to 10°.

- XHFV-FIX variant: Includes floor fixing options and allowing up to 4,000N tensile load. Available in foot diameters 65, 80, 105 and 125mm.

- XHFVG variant: These feet include a bolted connection for minimum play between the footplate and spindle. They support compression loads of up to 110.000N and can compensate for floor slopes of up to 9°.

- XHFVJ variant: These feet include a bolted connection for minimum play between the footplate and spindle. They support compression and tensile loads of up to 110.000N and 20.000N, respectively. The feet can compensate for floor slopes of up to 9°.

These feet have been replaced by the XHFV series; however, they are still available to existing customers. They enable lower minimum adjustment with high total adjustment and are 3-A certified together with a fully welded flange. They support compression loads of up to 110.000N.

- XHFG variant: Base variant without mounting holes

- XHFJ variant: Includes mounting holes and supports tensile loads of up to 20.000N.

Please Note: We also have a levelling feet in the model XHFVT which is very similar to our XHFV model, however, with a separate spindle and footplate. Our XHFVT levelling feet are certified by 3-A and USDA. We do not have this type visible on our website, however, contact our sales department to learn more!

The levelling feet that possess a "T" in their product group name have been designed with a separate footplate and spindle, while the product groups with a "FIX" or "J" in their product group name feature fixing options to the floor.

All our certified hygienic levelling feet feature a hygienic sleeve that covers the thread, preventing over-adjustment and ensuring safety against exposed threads. This sleeve also acts as a counter nut.

You can select the various product groups using the product group filter provided in the product finder above.

Read moreRead less