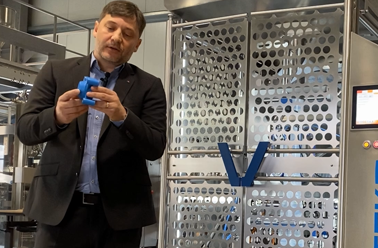

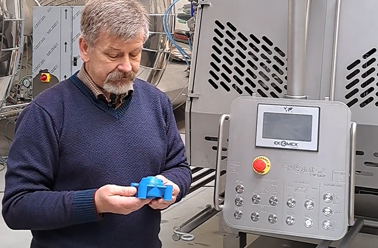

Future-Proofing Food Machinery: bePROTO's Collaboration with NGI for Cutting-Edge Solutions

bePROTO is a forward-thinking engineering company specializing in food industry machinery - they partner with NGI to deliver cutting-edge, high-quality, hygienic design to their customers.