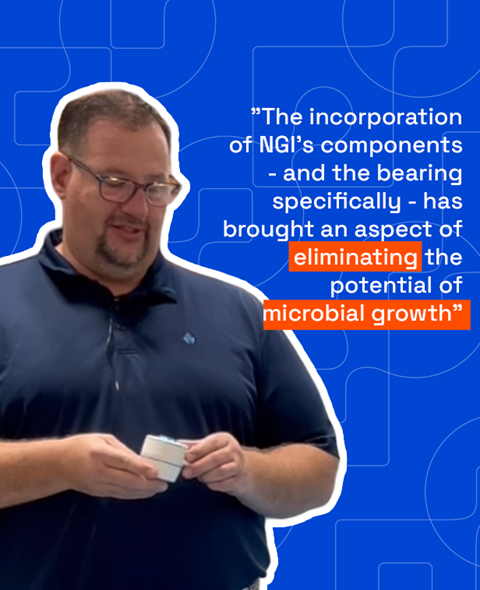

Chicago MetalCraft Elevates Hygienic Standards with NGI Components

At NGI, we are proud to partner with Chicago MetalCraft - a family-owned business that specializes in delivering hygienically designed euipment for the food industry. Together, we are committed to enhancing the safety, sanitation and overall quality of food production environments. Our componentas play a critical role in ensuring the Chicago MetalCraft's conveyors and supporting equipment meet the highest hygienic standards.