Key take aways from the testimonial includes:

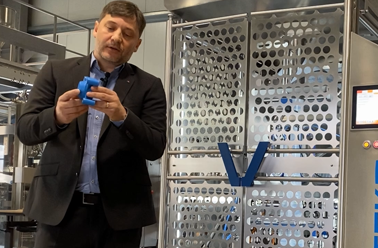

Ekomex has been producing machines for 25 years, catering to both small food processing factories and large-scale production lines.

- Focus on finding hygienic components

Hygiene is a top priority due to increasing regulations in the food industry. Ekomex uses components with sophisticated, hygienic designs to meet these requirements.

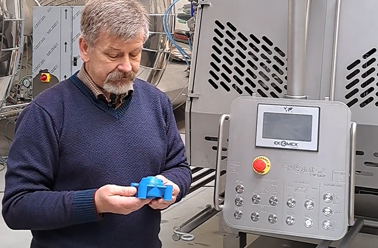

Ekomex chooses NGI products for their technical refinement and compliance with hygienic standards. NGI components ensure the machines meet high technical standards, which in turn satisfies Ekomex’s customers.

- Challenges solved by NGI Components

NGI bearings are reliable, precision-engineered, and have features like slanted edges that make them ideal for the food industry. These bearings can be easily swapped with older components, saving costs.

Ekomex values quality, reliability, and the documentation (certificates) provided by suppliers, all of which NGI excels in.