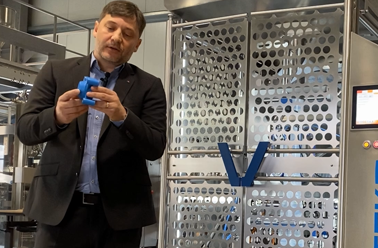

Highlights from VCU Robotics' testimonial includes:

- Pick-and-place robotic systems for the food industry:

VCU Robotics is a Netherlands-based start-up specializing in pick-and-place robotic systems for the food industry, especially fish processing. They focus on tackling diverse automation challenges, including six-axis robots and innovative product grippers.

- Time-Saving Innovation & Competitive Pricing

VCU Robotics discovered NGI’s hygienic bearings at a trade show, expecting high costs but finding them reasonably priced. NGI components simplify engineering by addressing hygiene challenges, providing high quality, easy-to-clean solutions with an excellent price-to-quality ratio.

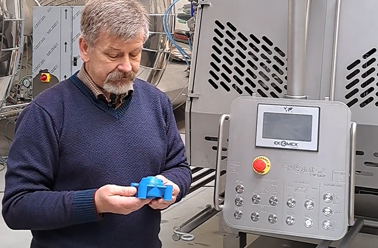

- Combat issues like listeria

Salmon processing companies benefit significantly from NGI components, which help combat issues like listeria caused by inadequate cleaning. NGI’s hermetically sealed and smooth-surfaced components ensure no bacteria-prone areas, supporting VCU’s hygiene-first policy.

Prevent bacterial growth by eliminating dead corners and ensuring a sealed, smooth surface. Enhance cleaning efficiency, reducing maintenance time and improving hygiene for conveyor belts.